5052 H32 Perforated Aluminium Plate

Chalco offers aluminum perforated plates for diverse industries. The punching machine produces plates up to 1.5m wide with hole diameters reaching 80mm (above 80mm, laser equipment is used). Additional services like cutting, welding, and pre-drilled fixing holes are available, offering a comprehensive solution for perforated metal plates.

Chalco's 5052 perforated plate is lightweight, corrosion-resistant, and welds well. In H32 temper, it offers moderate strength and enhanced processing. Widely used in construction, decoration, automotive filtration, screening, and isolation, it's suitable for larger and complex components due to excellent welding performance.

Hot selling size table of Chalco perforated plate

Chalco can provide aluminum perforated plate with different sheet sizes, thicknesses, hole diameter, hole spacing, staggered sizes, and hole rates according to customer requirements. The following table shows the sizes of hot selling round hole punched plates. For more sizes, please click to contact.Quick Quote

Size parameters

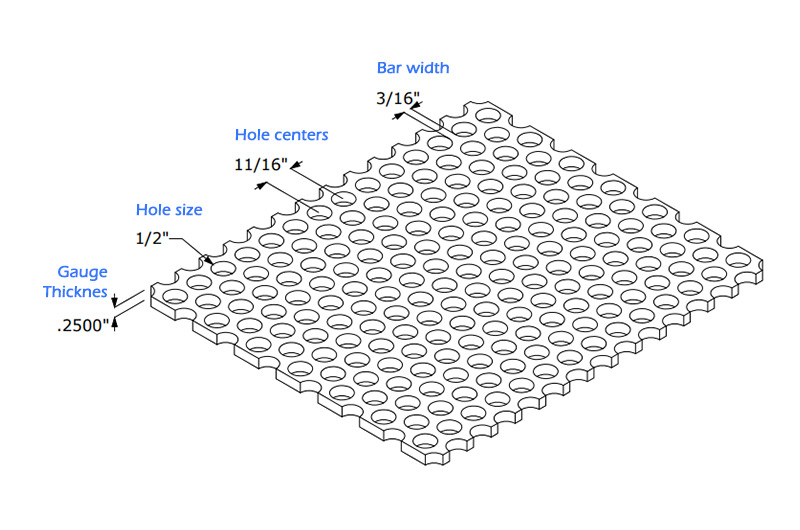

Hole type: round(60o staggered centers)

Gauge/Thickness: .2500"Thick(1/4"Gauge)

Hole size: 1/2" Hole centers: 11/16" Bar width: 3/16"

| Gauge / Plate thick. | Hole diameter | Hole centers | Open area |

|---|---|---|---|

| 26 | .020" RD | .045" Stag | 18% |

| 22 | 1/32" RD | 1/16" Stag | 23% |

| 24 | 3/64" RD | 5/64" Stag | 33% |

| 22 thru 18 | 3/64" RD | 3/32" Stag | 23% |

| 22 thru 16 | 1/16" RD | 3/32"Stag | 40% |

| 20 thru 16 | 1/16" RD | 7/64" Stag | 30% |

| 26 thru 16 | 1/16" RD | 1/8" Stag | 23% |

| 22 thru 14 | 5/64" RD | 1/8" Stag | 35% |

| 24 thru 14 | 3/32" RD | 5/32" Stag | 33% |

| 24 | 3/32" RD | 3/16" Stag | 23% |

| 18 | .117 RD | 5/32" Stag | 51% |

| 24 thru 11 | 1/8" RD | 3/16" Stag | 40% |

| 14 thru 12 | 1/8" RD | 7/32" Stag | 30% |

| 14, 13 | 1/8" RD | 1/4" Stag | 23% |

| 18 | 9/64" RD | 3/16" Stag | 51% |

| 22 thru 16 | 5/32" RD | 3/16" Stag | 63% |

| 20 thru 10 | 5/32" RD | 1/4" Stag | 35% |

| 22 thru 16 | 3/16" RD | 7/32" Stag | 67% |

| 24 thru 12 | 3/16" RD | 1/4" Stag | 51% |

| 10, 3/16" | 3/16" RD | 5/16" Stag | 33% |

| 14 thru 10 | 3/16" RD | 3/8" Stag | 23% |

| 20 thru 16 | 1/4" RD | 5/16" Stag | 58% |

| 26 thru 1/4" | 1/4" RD | 3/8" Stag | 40% |

| 20 | 17/64" RD | 5/16" Stag | 66% |

| 20 thru 1/4" | 5/16"RD | 7/16" Stag | 46% |

| 20 thru 1/4" | 3/8" RD | 9/16" Stag | 40% |

| 20 thru 1/4" | 1/2" RD | 11/16" Stag | 48% |

| 16 | 1/2" RD | 3/4" Stag | 40% |

| 10 thru 1/4" | 5/8" RD | 7/8" Stag | 46% |

| 16 thru 1/4" | 3/4" RD | 1" Stag | 51% |

| 10 thru 1/4" | 1" RD | 1-3/8" Stag | 48% |

| 1/4" | 1-1/4" RD | 1-5/8" Stag | 54% |

| 1/4" | 1-1/2" RD | 2" Stag | 51% |

| 1/4" | 2" RD | 2-1/2" Stag | 58% |

| 3/16" | 2-1/2" RD | 3" Stag | 63% |

| 3/16" | 3" RD | 3-1/2" Stag | 67% |

| 10 | 4" RD | 4-1/2" Stag | 72% |

Advantage of Chalco 5052 H32 aluminum perforated plate

- Marine grade alloy with excellent corrosion resistance, 5052 perforated plate can be used for building exterior walls, chemical industry equipment casings, etc.;

- The H32 temper provides the alloy with moderate strength and is less prone to deformation or fracture during the punching process.

- H32 temper provides good formability for alloys, which can easily form complex shapes through processes such as punching and molding, and is easy to cut and bend;

- 5052 alloy can be easily welded using various welding methods. This is beneficial for the manufacturing of larger and more complex components.

- The punching plate of 5052 H32 aluminum alloy is relatively lightweight and is popular for lightweight applications, especially in automotive front grilles.;

- The 5052 aluminum plate has good thermal conductivity and excels in heat dissipation, suitable for applications like electronic equipment casings.

Cooperative industry of Chalco 5052 H32 perforated plate

- Architectural fields such as exterior walls, screens, and ceilings;

- Outdoor landscape and decoration fields such as railings and outdoor decoration.

- Micro porous mesh screen punching plate.

- The casing, storage tanks, and pipelines of chemical equipment;

- Body structure, body panels, front grille and other components;

- Electronic equipment casing to ensure the heat dissipation effect of the equipment;

FAQ for purchasing Chalco perforated plate

How to choose the proper metal to your perforated plate project?

The best-selling metal perforated plate products in the market include perforated stainless steel plate, perforated galvanized steel plate, perforated brass plate, and perforated aluminum alloy plate. Aluminum alloy plate is occupying most of the metal perforated plate market due to its light weight, good corrosion resistance, good processing performance, and complete recyclability.

How to choose manufacturers and suppliers of perforated aluminum sheets?

Chalco has complete quality certification for high-quality perforated plates, with a complete range of products, large inventory, short delivery time, and can customize plate size, surface, hole diameter, opening rate, and hole pattern according to customer needs. Welcome to inquire and order.

Where can I buy perforated aluminum plates at a discounted price?

The cost of perforated metal plates depends on the type, thickness, and size of the plate, as well as the required design type.

Chalco, with its complete set of perforated aluminum plate production lines, can ensure the production and sales of perforated aluminum plates at the optimal prices.

How to calculate the weight of perforated plate?

Calculation of perforated metal sheet weight per square meter can be done as reference below:

ps = absolute (specific) weight (Kg) , v/p = open area (%) , s = thickness mm , kg = [s*ps*(100-v/p)]/100

Open area calculation when holes 60° staggered:

V/p = open area (%), D = holes diameter (mm), P = holes pitch (mm), v/p = (D2*90,7)/p2

S = Thickness in mm

D = Wire Diameter in mm

P = Pitch in mm

V = Open Area %

[Click to check the detailed information]

How to calculate the opening area of perforated plate?

[Click to check the detailed information]

Learn more items of perforated plate.