Focused on the aluminum industry, this blog explores the practical guidance for aluminum production and applications, and search the latest news in industry dynamics.

If you need to convert the dimensions of aluminum sheets to either metric or imperial units, please refer to the chart below.

7050 aluminum plate excels in stress corrosion cracking and fatigue strength, while 7075 is characterized by its high hardness.

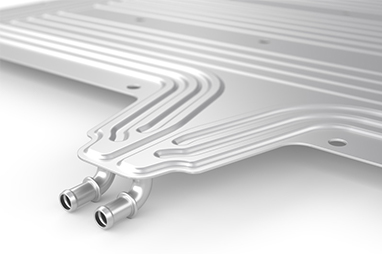

Chalco's new alloy enhances corrosion resistance in high-strength brazed composite water cooling plates for electric vehicles.

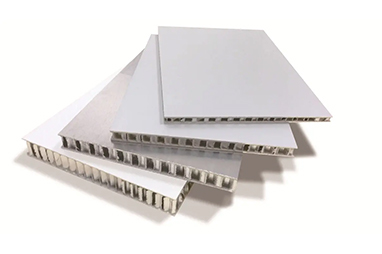

Drum peel strength exceeds 200 N mm/mm; compressive strength ranges 4-20 MPa; tensile strength surpasses 10 MPa.

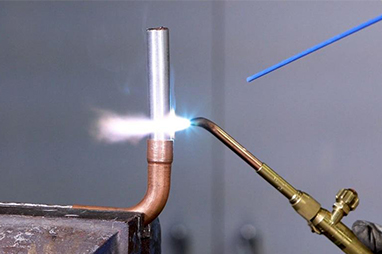

Analyzing five reasons for vacuum brazing leakage in heat exchangers and proposing corresponding measures to reduce or prevent such occurrences.

Chalco offers a variety of aluminum roofing sheets suitable for diverse climates, ensuring efficient protection and great aesthetics.

Color discrepancies in anodized aluminum plates are inevitable. Chalco will guide you to understand the reasons and solutions.

The significant differences between anodization and hard anodization lie in thickness, color, applications, and processes.

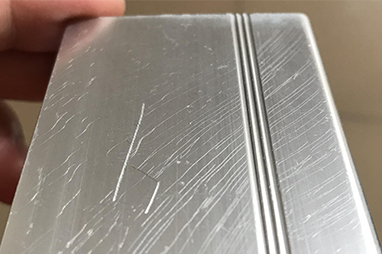

Chalco guides you in understanding the causes and prevention of cracks and peeling in aluminum sheet anodized oxide films.

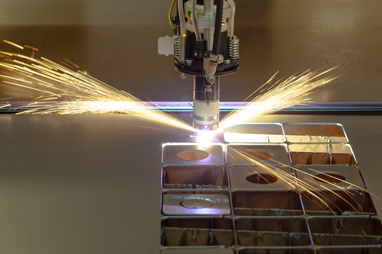

From the cost, characteristics, technical details to operating methods of cutting tools, providing you with the ultimate guide for aluminum sheet cutting solutions.

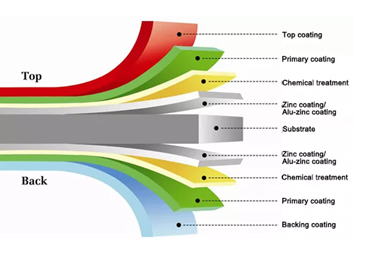

Chalco color-coated aluminum coils can use a variety of coating materials, the most common of which are PE and PVDF coatings.

Unveiling the applications of different surface-treated reflective aluminum panels, including color-coated mirrored panels, oxidized mirrored panels, black mirrored panels, etc., in the field of architectural decoration.