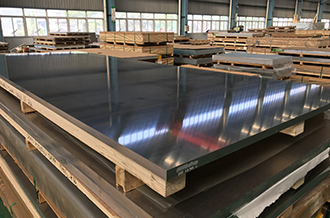

6082 T4 Aluminum Plate

Thickness: 0.15-600mm

Width: 20-2650mm

Specification:ASTM B209 / ASME SB209, EN485, EN573

6082 aluminum plate has the highest strength among the 6000 series aluminum alloys and excellent corrosion resistance and machinability. Due to its relatively higher strength, alloy 6082 has replaced alloy 6061 in many applications.

6082 alloy is popular in T6, T4, T651, T6511 and other tempers. The strength of 6082 aluminum plate in T4 temper is relatively low, but its formability is good, making it suitable for situations that require bending or high formability requirements.

Mechanical properties of 6082 T4 aluminum plate BS EN485-2

| Specified thickness mm | Tensile strength Rm/MPa | Yield strength Rp0.2/MPa | Elongation % | Bend radiusa | Hardness HBWa | |||

|---|---|---|---|---|---|---|---|---|

| Over | Up to | A50mm | A | 180° | 90° | |||

| 0.4 | 1.5 | 205 | 110 | 12 | - | 3,0 t b | 1,5 t b | 58 |

| 1.5 | 3.0 | 205 | 110 | 14 | - | 3,0 t b | 2,0 t b | 58 |

| 3.0 | 6.0 | 205 | 110 | 15 | - | - | 3,0 t b | 58 |

| 6.0 | 12.5 | 205 | 110 | 14 | - | - | 4,0 t b | 58 |

| 12.5 | 40.0 | 205 | 110 | - | 13 | - | - | 58 |

| 40.0 | 80.0 | 205 | 110 | - | 12 | - | - | 58 |

Chemical properties of 6082 T4 aluminum plate

| Element | Composition % (BS EN 573-3:2009 Alloy 6082) |

|---|---|

| Mn | 0.40 - 1.00 |

| Fe | 0.0-0.50 |

| Mg | 0.60-1.20 |

| Si | 0.70-1.30 |

| Cu | 0.0-0.10 |

| Zn | 0.0-0.20 |

| Ti | 0.0-0.10 |

| Cr | 0.0-0.25 |

| Mn | 0.40-1.00 |

| Fe | 0.0-0.50 |

| Other Each | 0.0-0.05 |

| Others Total | 0.0-0.15 |

| Al | Balance |

Thermal properties of 6082 T4 aluminum plate

| Thermal properties | Metric | English |

|---|---|---|

| Latent Heat of Fusion | 410 J/g | |

| Maximum Temperature: Mechanical | 170 °C | 330 °F |

| Melting Completion (Liquidus) | 650 °C | 1200 °F |

| Melting Onset (Solidus) | 580 °C | 1070 °F |

| Specific Heat Capacity | 900 J/kg-K | 0.21 BTU/lb-°F |

| Thermal Conductivity | 160 W/m-K | 95 BTU/h-ft-°F |

| Thermal Expansion | 23 µm/m-K |

Features of 6082 T4 aluminum plate

- By appropriate melting and casting processes, aluminum plates can have a uniform microstructure and composition.

- Strict quality control measures are taken throughout the manufacturing process to ensure the stability of quality.

- Manufacturing according to specifications, with precise dimensions and tolerances.

- The surface of the board is free of defects, smooth and uniform, meeting the specified requirements, and free of defects such as scratches, dents, and cracks.

- 6063 T4 aluminum plate is ensured to have the required mechanical properties, including strength, ductility, and hardness, through comprehensive and consistent testing.

Application of 6082 T4 aluminum plate

- In marine engineering, it is used to manufacture structural components such as hulls, decks, and bridges.

- In the national defense industry, it is used to manufacture warship bodies, decks, military aircraft, and missile launch platforms.

- In transportation, structural components used for rail transit vehicles (such as trains, subways), trucks, and other transportation vehicles

- In the field of automobile manufacturing, it is applied to body structures, frames, vehicle doors and windows, and other components.

- In the field of mechanical manufacturing, it is applied to manufacture various mechanical structural components, such as molds, machine tool components, etc.

Related products