Aluminum Foam Sheet

Foam aluminum panels also have the characteristics of strong impact resistance, outstanding thermal insulation performance, good permeability, and superior specific stiffness.

Its thermal conductivity is only about 1/400 of pure aluminum, providing excellent insulation. Excellent permeability allows for the convenient flow of liquids and gases.

Its bending stiffness is 1.5 times that of steel, enabling it to withstand greater bending stress and enhance the stability of structures.

Specifications of foam aluminum panels

Standard size: 2000 X 1000mm

Width: 1000 mm

Thickness: 5mm-250mm

Aperture: 1-3 mm, 3-5mm, 5-7mm, 7-13mm(Large pores with strong light transmittance)

Density: 0.25-0.3

Weight: 3KG X width

Package: Within 10 boards, you can use the double-layer sandwich packaging method. For more than 10 boards, you can use wooden boards to nail wooden boxes.

Foam aluminum plate classification

Chalco offers a variety of foam aluminum panels, including perforated, closed-cell, AFS foam aluminum sandwich panels, as well as Porous aluminum, and other different types.

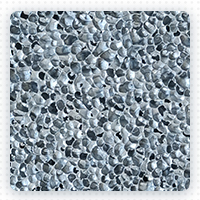

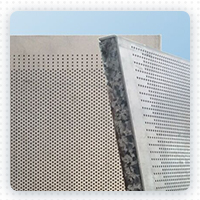

Perforated Foam Aluminum Panel

The metal properties and porous structure of perforated foam aluminum panels make them excellent for sound absorption, fire resistance, as well as features like dust resistance, environmental friendliness, and waterproofing. Therefore, they can be used for an extended period in various complex environments to reduce noise.

| Properties of perforated foam aluminum panel | |

|---|---|

| Aperture | 0.5-10 mm |

| void ratio | 70%-90% |

| F | 55%-65% |

| Density(G/CM3) | 0.25-1.05 |

| Electromagnetic shielding (DB) | 60-90 |

| Bending strength (Mpa) | ≥27 |

| Compressive strength (Mpa) | >44 |

| Sound absorption coefficient (%) | 0.52-0.85 |

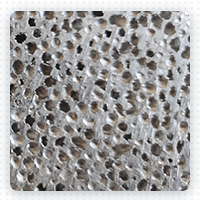

Closed-cell foam aluminum

Closed-cell foam aluminum has better thermal insulation and energy absorption compared to open-cell foam aluminum.It exhibits excellent insulation and shock absorption properties, making it suitable for applications such as automotive shock absorption and bridge collision prevention.

| Properties of Closed-cell foam aluminum | |

|---|---|

| Aperture | 4-8 mm |

| void ratio | 75%-90% |

| F | none |

| Density(G/CM3) | 0.25-0.70 |

| Electromagnetic shielding (DB) | 60-90 |

| Bending strength(Mpa) | 3-15 |

| Compressive strength (Mpa) | 3-17 |

| Sound absorption coefficient (%) | 40-80 |

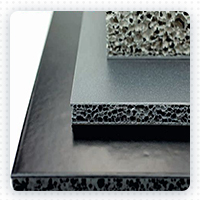

AFS aluminum foam sandwich

Foam aluminum sandwich panel is an innovative material with a three-layer structure. It is primarily composed of a formed aluminum core, perfectly sandwiched between two aluminum cover layers.The unique cover layers are made of metal material and are fused to the core layer without the need for adhesives, ensuring the stability and strength of the entire panel.

| Properties of AFS aluminum foam sandwich | |

|---|---|

| Alloy | 6082, 5754 |

| Thickness | 9-80 mm |

| Cover thickness | 0.75-10 mm |

| Common sizes | 1000mm×2000 mm |

| Flatness of plate | 1mm/1000 m |

| Thickness tolerance | +/-0.5 mm |

| Surface weight | 10.5kg/m2 |

| Tensile Strength | 120-200 MPa |

| Compressive strength | 4-8 MPa |

| Thermal expansion | 25×10-6 1/K |

| Thermal Conductivity | 0-15W/mK |

Porous aluminum plate

Porous aluminum plate is a new type of aluminum material with numerous small pores, and their positions can be controlled as needed.

There are two types: one where the pores are independent, and the other where the pores are interconnected. Porous aluminum is widely used in various applications due to its light weight, high hardness, and versatile functionality.

Porous structure: the pores are small and numerous. Porous aluminum is extremely light, with a density of less than 1/10 of aluminum.

Specific surface area: 10-40 cm²/cm³ (more pores, larger surface area)

High damping performance: porous aluminum plates exhibit a delayed response when force is applied, slowing down impacts. This makes porous aluminum plates very useful in manufacturing impact-resistant components. Additionally, the effect of porous aluminum plates depends on the size of the pores, and this effect can be adjusted by modifying the gap.

Special acoustic properties: porous aluminum plates can absorb sound and reduce noise. Smaller pores result in better sound absorption, and this effect can be adjusted by changing the size and shape of the pores.

Excellent fluid permeability: porous aluminum plates act as filters, effectively removing solid particles from liquids or gases. The material is suitable for various filtration and flow control needs, such as high-temperature dust collectors.

Outstanding surface exchange capacity: the large surface area of porous aluminum plates significantly increases the contact area between fluid and material surface. Porous aluminum plates can be used as excellent materials for making heaters and heat exchangers.

Advantages of foam aluminum panels

Foam aluminum panels, due to their unique porous structure, offer advantages such as lightweight, high strength, good sound absorption, adjustable thermal conductivity, and electromagnetic interference shielding, making them widely applicable in various fields.

Small density, high stiffness-to-mass ratio

Foam aluminum exhibits a small density, high stiffness-to-mass ratio, and excellent energy absorption due to its porous structure.

Good sound insulation and absorption

The voids between foam aluminum panels can scatter sound waves, causing the waves to diffuse and attenuate within the material.

The sound absorption performance of foam aluminum panels is influenced by factors such as pore size, porosity, and pore uniformity.

Excellent thermal insulation

Foam aluminum panels are widely used in industry for thermal insulation because they effectively reduce the transfer of heat between different areas.

High electromagnetic shielding performance

With its unique structure, foam aluminum panels can effectively block electromagnetic waves. Due to their high strength, they can also absorb electromagnetic waves, making them suitable for use as wall materials in some research applications.

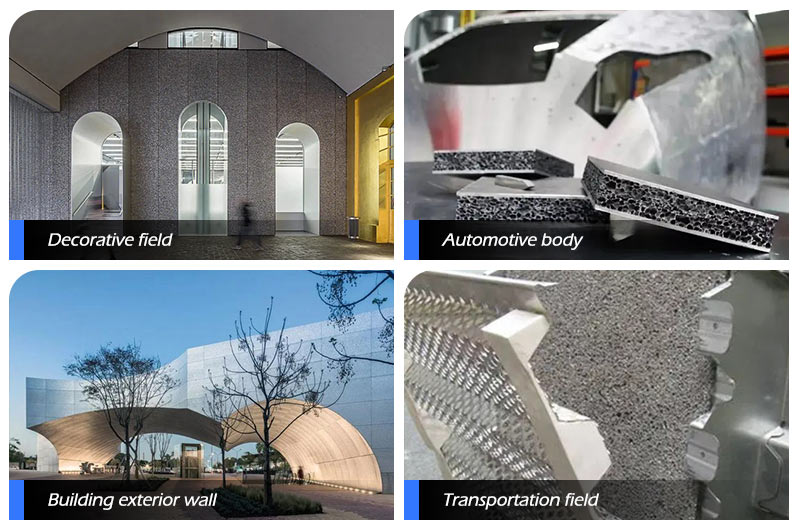

Applications of aluminum foam

Foam aluminum material possesses a series of excellent properties such as lightweight, high specific strength, vibration reduction, energy absorption, sound absorption, thermal insulation, and flame retardancy.

It has realized the integration of material structure and functionality, offering broad application prospects in various fields such as transportation, military aerospace, and construction.

Transportation

Foam aluminum panels serve as sound barriers on elevated bridges, highways, and railways, reducing traffic noise and vibrations.

This not only meets the demand for lightweight materials but also contributes to energy conservation.

Automotive

In the automotive industry, where lightweight and fuel efficiency are pursued, foam aluminum panels, being lightweight and high in stiffness, are instrumental in addressing these trends.

Using foam aluminum panels in the structure of the vehicle can significantly enhance collision safety and performance.

Incorporating foam aluminum into different parts of the vehicle body, such as energy-absorbing boxes, crash beams, A-pillars, etc., can effectively strengthen the structure's strength, rigidity, and energy absorption performance.

Aerospace

Foam aluminum panels are highly favored in the aerospace industry due to their high hardness, lightweight, excellent resistance to compression, and cost-effectiveness.

They are widely used in critical areas such as helicopter tail fins, protective structures, turbines, sealing rings for aircraft engines, support structures for spacecraft shells, and landing cushioning structures for lunar rovers, demonstrating outstanding performance.

Military Equipment

Foam aluminum panels play a crucial role in military electromagnetic shielding. They can effectively block high-power electromagnetic signals within military vehicles, radar equipment, and other devices, surpassing traditional materials in effectiveness.

Foam aluminum panels are also used to manufacture lightweight and sturdy military equipment, including airdrop containers, tank protective armor, submarine bulkheads, and more.

Construction

The application of foam aluminum in the construction industry can be divided into two main aspects. Firstly, utilizing the sound absorption and energy absorption properties of foam aluminum panels, they can be used as decorative sound-absorbing materials in large-span structures such as stadiums and exhibition halls.

Secondly, taking advantage of the energy absorption and vibration reduction capabilities of foam aluminum, it can be used in military and protective engineering construction, protective doors, etc.

Foam aluminum panels also possess characteristics such as thermal insulation and fire resistance, making them suitable for applications like fire doors and interior wall decorative panels.