Aluminum Mirror Sheet

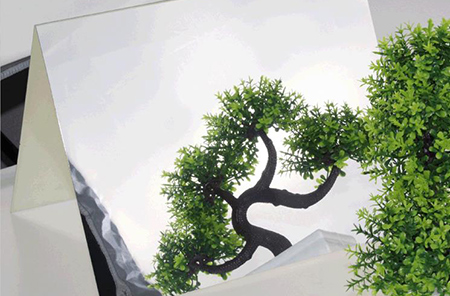

Mirror aluminum sheets are aluminum plates processed through rolling and polishing techniques to achieve a high reflective effect. The rolling process creates a smooth surface, while polishing generates the reflective mirror effect.

Mirror aluminum sheets - Chalco, the best supplier

- As one of China's largest aluminum material suppliers, Chalco offers mirror aluminum sheets in the 1000, 3000, 5000, and 8000 series, with a reflectivity typically reaching 86% or higher.

- Chalco provides standard mirror panels and one-sided mirror panels, available in customized sizes and thicknesses according to customer requirements.

- Chalco's mirror aluminum sheets undergo various processing steps such as mechanical polishing, chemical polishing, electrolytic polishing, and surface treatment, ensuring a smooth surface and excellent durability.

- With multiple surface treatment production lines, Chalco offers embossed mirror aluminum coil, color-coated mirror aluminum sheets, anodized mirror aluminum sheets, and other products, allowing customization of specific patterns and colors based on customer demands.

- As a primary source supplier, Chalco maintains impeccable quality certifications, enabling bulk customization with short delivery times and competitive pricing.

Chalco's hot selling mirror aluminum products

1000 series mirror aluminum sheet

Reflectivity: ≥86%

Alloys: 1050, 1060, 1070, 1085, 1100

Conditions: O, H12, H14, H18, H19

Contact us now

Thickness: 0.2-6.0mm

Width: 200-2000mm

Standard Sizes: 10002000mm, 12002400mm, 1220*2440mm

Features: High purity, good formability, excellent processability

Applications: Lighting reflector covers and fixture decoration, signage, solar reflectors, etc.

Note: The 1000 series mirror aluminum exhibits lower hardness. Despite its good reflectivity and decorative properties, surface protection is advised during use to maintain its appearance and performance.

3000 series mirror aluminum sheet

Reflectivity: ≥86%

Alloys: 3003, 3004, 3005, 3104, 3105

Conditions: H12, H14, H16, H18, H24

Contact us now

Thickness: 0.2-6.0mm

Width: 200-2000mm

Standard Sizes: 10002000mm, 12002400mm, 1220*2440mm

Features: Higher hardness compared to the 1000 series, good anti-rust properties, excellent bending performance

Applications: Architectural decoration, automotive interior and exterior decoration, cookware, luggage, jewelry boxes, etc.

5000 series mirror aluminum sheet

Reflectivity: ≥86%

Alloys: 5005, 5052, 5083, 5182

Conditions: H14, H16, H18, H24, H26

Contact us now

Thickness: 0.2-6.0mm

Width: 200-2000mm

Standard Sizes: 10002000mm, 12002400mm, 1220*2440mm

Features: Stronger, more durable, excellent corrosion resistance

Applications: Architectural curtain wall, automotive interior and exterior furniture, household appliance casing, etc.

8000 series mirror aluminum sheet

Reflectivity: ≥86%

Alloys: 8011, 8014

Conditions: H14, H16, H18, H21, H24, H26

Contact us now

Thickness: 0.2-6.0mm

Width: 200-2000mm

Standard Sizes: 10002000mm, 12002400mm, 1220*2440mm

Features: Smooth surface (Roughness Ra≤20nm), high reflectivity, high formability, high elongation rate (≥40%)

Applications: Stealth fighter skin, solar absorber and reflector plates, high-end equipment such as automotive and architectural decorative parts

Chalco mirror aluminum specialty product

Colored mirror aluminum sheet

Colored mirror aluminum sheet is a type of mirror aluminum formed by a special scratch-resistant transparent coating that is baked to provide surface protection and excellent durability. Primarily used in architectural facades, ceilings, and interior decoration projects.

Colored mirror aluminum sheet characteristics

- High Reflectivity: Offers over 85% reflectivity, enhancing lighting efficiency in fixtures.

- Versatility: Convenient to process, available in various colors, suitable for diverse design needs.

- Easy Maintenance: Exceptional stain resistance and ease of cleaning, suitable for long-term use.

- Outstanding Performance: Heat-resistant, good formability, and high abrasion resistance.

Applications of colored mirror aluminum sheet

Extensively used in lamp reflectors, household appliance panels, interior decoration, among others. It can replace stainless steel mirror panels and anodized aluminum mirror panels, reducing costs and improving efficiency.

Colors of colored mirror aluminum sheet

Colored mirror aluminum generally comes in two main categories: basic colors and metallic colors, as detailed below:

| Basic Colors | Metallic Colors |

|---|---|

| 790.36 Chinese Red Mirror Aluminum Sheet | 790.23 Titanium Gold Mirror Aluminum Sheet |

| 790.32 Orange Mirror Aluminum Sheet | 790.26 Champagne Mirror Aluminum Sheet |

| 790.20 Gold Mirror Aluminum Sheet | 790.35 Red Copper Mirror Aluminum Sheet |

| 790.50 Green Mirror Aluminum Sheet | 790.30 Rose Gold Mirror Aluminum Sheet |

| 790.62 Cyan Mirror Aluminum Sheet | 790.70 Light Antique Copper Mirror Aluminum Sheet |

| 790.40 Blue Mirror Aluminum Sheet | 790.73 Dark Antique Copper Mirror Aluminum Sheet |

| 790.42 Ice Blue Mirror Aluminum Sheet | 790.16 Stainless Steel Mirror Aluminum Sheet |

| 790.60 Purple Mirror Aluminum Sheet | |

| 790.18 Smoke Mirror Aluminum Sheet | |

| 790.17 Black Mirror Aluminum Sheet |

Mirror finish anodized aluminum sheet

Anodized mirror finish aluminum sheet refers to aluminum sheets that have undergone processes like polishing, buffing, and rolling to achieve a mirrored effect. The surface appears smooth, even, and highly glossy, and further treatment involves surface oxidation to create a dense oxide film, enhancing scratch resistance and weatherability. It is commonly used as a high-end decorative material.

Features of anodized mirror finish aluminum sheet

- Lightweight, moisture-resistant, and fire-resistant

- High strength, lightweight, and strong corrosion resistance

- Uniform coating with various color options

- Easy to clean and maintain, simple and fast installation

- Environmentally friendly and recyclable

Applications of anodized mirror finish aluminum sheet

Widely used in architectural facades, interior decoration, high-end electronic product casings, home appliance enclosures, and other fields. It offers diverse design options and demonstrates strong environmental compatibility.

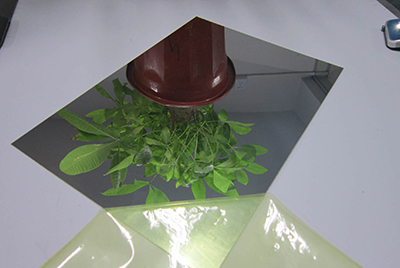

Polished Mirror Finish Aluminum Sheet vs. Anodized Mirror Finish Aluminum Sheet

- Polished mirror finish aluminum sheet exhibits a brighter and more aesthetically pleasing appearance with a relatively higher reflectivity but is prone to damage.

- Anodized mirror finish aluminum sheet possesses a dense oxide film on the surface, enhancing corrosion resistance and durability.

- Anodized mirror finish aluminum sheet offers a wider range of colors, appearing more splendid and possessing stronger decorative qualities.

Embossed aluminum mirror sheet

Embossed aluminum mirror sheets, also known as mirror embossed aluminum or polished embossed aluminum, are achieved by processing pre-polished mirror aluminum sheets with embossing rollers. They are typically used for decorative purposes or to reduce surface reflectivity. There are various types of embossed aluminum materials, including hammered patterns, orange peel patterns, diamond patterns, spherical patterns, and more, which can be customized according to customer requirements.

Hammered pattern aluminum embossed sheet

Made from mirror-finished anodized aluminum substrate with a surface featuring pebble-sized convex patterns, offering a diffuse light effect with a reflectivity of up to 86%. Widely used in the lighting and decoration industries.

Orange peel embossed aluminum mirror sheet coil

Displays a surface texture resembling an orange peel (or insect patterns), extensively used in applications such as refrigerator liners, air conditioning units, and packaging.

Diamond pattern mirror finish aluminum sheet

The surface is exceptionally smooth, with a reflectivity close to 90%. Widely utilized for decorative purposes like wall protection panels and door kick plates.

The production process of Chalco mirror aluminum

Mechanical polishing

Initially, diamond grinding wheels are used to polish the surface of aluminum alloy until it becomes smooth. Following the polishing, a sodium nitrate water solution is applied to prevent abrasions that might affect the overall aesthetics.

Electrochemical polishing

Subsequently, a mixture of phosphoric acid, nitric acid, and sulfuric acid is employed for the chemical and electrochemical polishing of the aluminum profiles.

Surface treatment

The finely polished mirror-finish aluminum sheets undergo additional surface treatments such as anodizing, coloring, embossing, and others.

Chalco's production process for mirror aluminum sheets encompasses various techniques, including mechanical polishing, chemical polishing, electrochemical polishing, and surface treatments. These methods are employed to achieve a smooth, durable, and highly reflective mirror effect.

Buying Chalco mirror aluminum sheets: things to consider

Q: Which type of mirror aluminum should I choose?

A: For applications where high reflectivity is needed without emphasizing durability, polished aluminum mirror sheets are a good choice. However, if durability and scratch resistance are important factors, anodized aluminum mirror sheets are more suitable.

Q: How should I select the thickness of aluminum mirror sheets?

A: Aluminum mirror sheets are available in various thicknesses, and the choice should depend on the specific application. Thicker aluminum mirror sheets are better suited for applications that require higher durability, such as household appliance casings and automotive decorative uses.

Q: How should I determine the size of aluminum mirror sheets?

A: Aluminum mirror sheets come in various sizes, and choosing the appropriate size should depend on the specific application scenario. Larger aluminum mirror sheets are typically used in commercial and industrial applications, while moderate sizes can be custom-fitted based on project requirements.

Q: What are the different surface treatment methods for aluminum mirror sheets?

A: Aluminum mirror sheets can undergo various surface treatments such as polishing, brushing, coloring, embossing, and anodizing. The appropriate treatment method depends on the desired aesthetics and the intended application. For instance, if you need lampshades, embossed hammer pattern mirror aluminum sheets may be suitable, while for architectural curtain walls, anodized mirror aluminum sheets would be more advisable due to their higher durability.