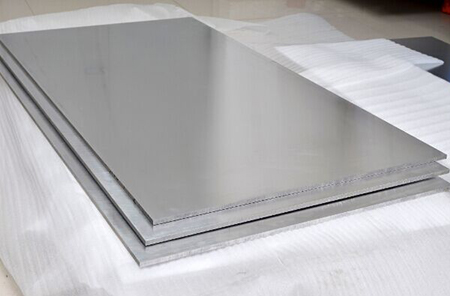

Precision Aluminum Plate

Precision aluminum plates are high-quality precision-cast aluminum plates manufactured through strict tolerance control and accurate processing. They undergo precision grinding or specialized sawing processes, possessing minimal stress, fine grains, and a uniform microstructure.

These plates find wide application in fixtures, securing devices, various gauges, workbenches, specialized machinery, and precision components.

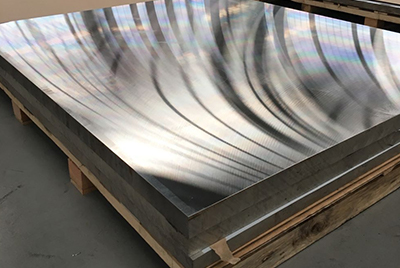

Chalco aluminium precision sawing plate

Chalco specializes in cutting within extremely tight tolerances, with the minimum thickness tolerance reaching as precise as 0.005". We possess state-of-the-art saws and other cutting equipment capable of handling large batches of products effortlessly.

Precision sawing plate

Thickness: 6-1000mm

Max size: 2670x6000mm

Regular size: 1470x3000mm, 2500x3000mm

Contact us now

Product specifications

Alloy: 5052, 5083

Temper: H112, H32

Thickness Tolerance: 0/+1mm (for t ≤ 250mm); 0/+3mm (for t > 250mm)

Surface Treatment: Six-face sawn

Surface Roughness: ≤30 µm

Flatness: ≤0.4mm/㎡

Stock thickness

Standard thicknesses range from 100-600mm and are readily available in stock. They can be sawn or customized to meet your requirements.

| 100mm | 150mm | 200mm | 250mm | 300mm | 350mm |

|---|---|---|---|---|---|

| 400mm | 450mm | 500mm | 550mm | 600mm |

Physical properties

| Density g/cm3 | Thermal Conductivity W/(mk) | Electrical Conductivity m/Ωmm2 | Mlodulus of Elasticity GPa | Coefficient of Thermal Expansion *10-6/K | |

|---|---|---|---|---|---|

| 5052 | 2.68 | 130-150 | 19-21 | 70 | 23.8 |

| 5083 | 2.66 | 110-140 | 16-19 | 70 | 24.2 |

Mechanical performance

| Ultimate Tensile Strength MPa(N/mm2) | Yield Strength MPa(N/mm2) | Elongation A5% | Brinell Hardness HB | |

|---|---|---|---|---|

| 5052 | 160-220 | 60-90 | 20-30 | 45-60 |

| 5083 | 220-300 | 110-140 | 10-20 | 70-85 |

Characteristics

- Excellent high-temperature resistance

- Cut with high-speed stability

- Can be divided into multiple specified sizes

- Uniform microstructure

- Option for single or double-sided precision milling

Typical applications

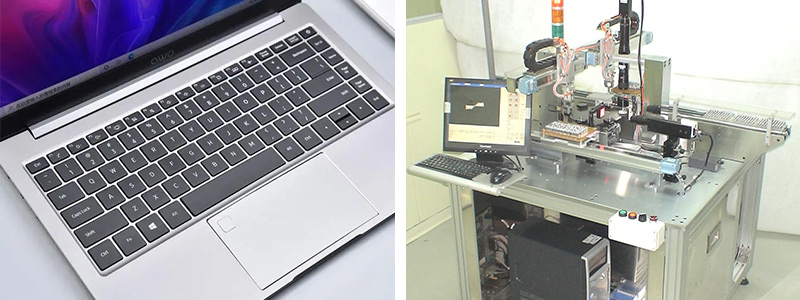

- Various low-pressure rapid molds

- Semiconductor manufacturing devices

- Industrial robots

- Vacuum chambers

- Mechanical equipment and components, among others

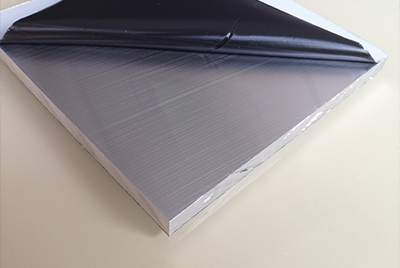

Chalco ultra-high precision aluminum plates

Chalco's precision milled panels undergo unique homogenization treatment and annealing, resulting in low residual stress, no deformation, and stable dimensions. They exhibit uniform grain structure and mechanical properties, dense organization, and low porosity. These panels have good machinability and weldability, excellent polishability, and strong corrosion resistance.

Ultra-high precision plate

Thickness: 6-250mm

Max size: 2500x6000mm

Regular size: 1470x3000mm, 2500x3000mm

Contact us now

Product specifications

Alloy: 5052, 5083

Temper: H112, H32

Thickness Tolerance: ±0.12mm

Width Tolerance: ±6mm

Length Tolerance: ±10mm

Surface Treatment: Six-sided sawing, two-sided precision milling, film coating

Surface Roughness: ≤0.4 µm

Flatness: ≤0.35mm/㎡(t≤15mm); ≤0.13mm/㎡(t>15mm)

Physical properties

| Density g/cm3 | Thermal Conductivity W/(mk) | Electrical Conductivity m/Ωmm2 | Mlodulus of Elasticity GPa | Coefficient of Thermal Expansion *10-6/K | |

|---|---|---|---|---|---|

| 5052 | 2.68 | 130-150 | 19-21 | 70 | 23.8 |

| 5083 | 2.66 | 110-140 | 16-19 | 70 | 24.2 |

Mechanical performance

| Ultimate Tensile Strength MPa(N/mm2) | Yield Strength MPa(N/mm2) | Elongation A5% | Brinell Hardness HB | |

|---|---|---|---|---|

| 5052 | 160-220 | 60-90 | 20-30 | 45-60 |

| 5083 | 220-300 | 110-140 | 10-20 | 70-85 |

Characteristics

- Extremely precise surface

- Very uniform flatness

- Extremely low residual stress

- Excellent corrosion resistance

- Very good homogeneity

- High strength

Typical applications

- Semiconductor manufacturing devices

- LCD manufacturing devices

- Solar panel manufacturing devices

- Medical instruments

- Office automation equipment

- Optical instruments

- Tooling and fixtures

Chalco precision aluminum plate for anodizing

Chalco's precision plates for anodizing undergo a unique homogenization treatment and annealing with specifically developed heat treatment parameters. This process significantly reduces residual stress, resulting in denser grain structure and lower porosity. They exhibit exceptional anodizing and hard anodizing properties, meeting the highest technical and optical application standards.

Precision plate for anodizing

Thickness: 6-250mm

Max size: 2500x6000mm

Regular size: 1470x3000mm, 2500x3000mm

Contact us now

Product specifications

Alloy: 5052, 5083

Temper: H112, H32

Thickness Tolerance: ±0.12mm

Width Tolerance: ±6mm

Length Tolerance: ±10mm

Surface Treatment: Six-sided sawing, two-sided precision milling, anodizing, film coating

Surface Roughness: ≤0.4 µm

Flatness: ≤0.35mm/㎡(t≤15mm); ≤0.13mm/㎡(t>15mm)

Physical properties

| Density g/cm3 | Thermal Conductivity W/(mk) | Electrical Conductivity m/Ωmm2 | Mlodulus of Elasticity GPa | Coefficient of Thermal Expansion *10-6/K | |

|---|---|---|---|---|---|

| 5052 | 2.68 | 130-150 | 19-21 | 70 | 23.8 |

| 5083 | 2.66 | 110-140 | 16-19 | 70 | 24.2 |

Mechanical performance

| Ultimate Tensile Strength MPa(N/mm2) | Yield Strength MPa(N/mm2) | Elongation A5% | Brinell Hardness HB | |

|---|---|---|---|---|

| 5052 | 160-220 | 60-90 | 20-30 | 45-60 |

| 5083 | 220-300 | 110-140 | 10-20 | 70-85 |

Characteristics

- Excellent anodizing performance

- Extremely low microporosity

- Very fine-grained structure

- Excellent polishability

- Precision milled surface

- Very good flatness

- Extremely low tension level

- Excellent corrosion resistance

Typical applications

- Consumer electronic product exteriors

- Automated instrument equipment

- Optical devices

- Mechanical engineering equipment

- Medical and laboratory equipment

- Tooling and fixtures

Precision aluminum plate FAQs

Q: What production equipment is needed for precision aluminum plates?

A: Chalco utilizes stable gantry milling machines with over 2 meters wide milling heads to create precision, accuracy, and unique surface characteristics. Each plate undergoes checks for thickness, flatness, and surface roughness, and is finally surface-protected with black and white films.

Q: How are tolerances achieved in precision aluminum plates?

A: Precision aluminum plates provided by Chalco adhere to very strict tolerance controls (± 0.002 inches), aiding in saving spindle time, simplifying clamping processes, and avoiding concerns about cutter taper and secondary operation fixtures.

Q: How does precision aluminum plate improve production efficiency?

A: Aluminum billets, after precision grinding, significantly enhance dimensions and accuracy, eliminating the need for adjustments to the parts before final machining, thereby improving the production rate or throughput of machining centers.

Q: What are the advantages of using precision aluminum plates?

A: Chalco's precision aluminum plates reduce setup and preparation time, eliminating the need for self-grinding, sawing, flattening, and squaring of blanks, significantly improving production efficiency and reducing labor costs.

Q: Are there processing standards for precision aluminum plates?

A: Chalco's precision processed aluminum cast plates meet high standards regarding thickness tolerance, flatness, parallelism, surface roughness, and give significant attention to basic values such as physical, metallurgical, and technical performance.

Q: What unique technical processes are involved in precision aluminum plates?

A: Through special heat treatments and unique sawing processes, Chalco's aluminum plates exhibit minimal stress, fine grain, uniform microstructure, high strength values, and are unaffected by directional properties.