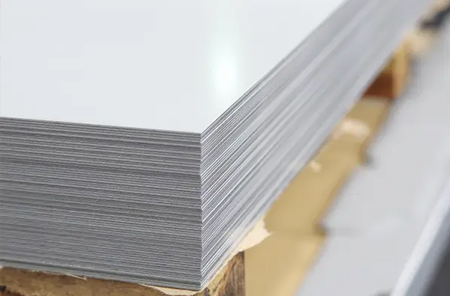

White Coated Aluminum Sheet Coil

White coated aluminum coil, using aluminum coil strip as the base material, undergoes surface paint coloring treatment. It features low cost, easy processing, corrosion resistance, and long service life. It is commonly used for trailer skin, side panels, and lining.

Chalco maintains a comprehensive stock of various sizes, can deliver in the form of cut aluminum sheets or coils according to customer requirements, and offers free samples.

Chalco white color coated aluminum coil purchase notes

- Chalco performs color matching based on the RAL and Pantone international color charts or customer samples, ensuring uniform and enduring colors with fine texture and no color deviation.

- The surface is smooth without compound high-temperature indentations, and the sheet has no residual stress, maintaining shape integrity after shearing without burrs.

- Chalco maintains a diverse stock of white color coated aluminum coil in various sizes, with a very low minimum order quantity, and ensures delivery within one week.

- Chalco is the original factory for white color coated aluminum coil, offering extremely competitive factory prices.

Specifications of white color coated aluminum coil

- Aluminum sheet processing methods: Cast rolling, hot rolling

- Coating thickness: 5-40μm

- Coating types: Epoxy, Polyurethane (PU), Polyester (HDP), Silicone Modified Polyester (SMP), Fluorocarbon (PVDF)

- Standards: ASTM-B-209M, BS EN 485-2, BS EN 573-3, GB/T3880-2008, EN 13501-1 A2, EN 45545

- Surface protection: Covered with PE/PVC film (according to customer requirements)

Hot-selling colors and sizes of white color coated aluminum coil

We offer a variety of stocked sizes for you to choose from, and prompt delivery is available.

-

Polar White coated aluminum sheet

Thickness: 0.020", 0.032", 0.040", 0.050", 0.063", 0.080"

Width x Length: Can be cut

-

Super Bright White coated aluminum sheet

Thickness: 0.032", 0.040", 0.050", 0.063", 0.080"

Width x Length: Can be cut

-

Crystal White coated aluminum sheet

Thickness: 0.030", 0.050"

Width x Length: Can be cut

-

Matte White

Thickness: 0.024", 0.032", 0.040", 0.050", 0.063"

Width x Length: Can be cut

-

Pearl White

Thickness: 0.063"

Width x Length: Can be cut

-

Ivory White

Thickness: 0.04", 0.063"

Width x Length: Can be cut

If the required sizes are not currently available in our stock, feel free to contact us for customization. We are dedicated to serving you wholeheartedly.

Application classification of white color coated aluminum coil

Trailer-Use Color Coated Aluminum Coil

White color coated aluminum coil has the characteristics of high strength, easy processing, excellent weather resistance, and corrosion resistance, making it an ideal material for processing trailer skins, side panels, and lining.

- Aluminum Alloys: 3003, 3105, 5052

- Temper: H14, H24, H291

- Common Thickness: 0.025", 0.032", 0.040", 0.050"

- Common Sizes: 49" x 96", 49" x 110", 49" x 120"

- Characteristics: High flatness, easy to process

- Packaging: Cut into aluminum sheets or coils

Aluminum Traffic Signs

Aluminum traffic signs have moderate strength, excellent corrosion resistance, and weldability. They are easy to shape, affordable, and have good weather resistance.

- Aluminum Alloys: 1050, 1060, 3003, 5052

- Temper: H14, H34, H38

- Common Thickness: 0.040", 0.063", 0.080", 0.100", 0.125"

- Common Widths: 30", 36", 48"

- Length: Customizable

- Characteristics: Smooth surface, high gloss, easy to paint

- Packaging: Cut into aluminum sheets or coils

- Processing: Perforation, cutting, bending

White Color Coated Aluminum Coil for Construction

White color coated aluminum coil is used to manufacture roofing panels, wall panels, curtain wall panels, interior decorative panels, ceiling panels, honeycomb panels, thermal insulation panels, rolling shutters, blinds, and more.

- Aluminum Alloys: 1050, 1060, 1100, 3003, 5052

- Common Thickness: 1.0mm, 1.5mm, 2.0mm, 2.5mm, 3.0mm, 4.0mm (0.0394", 0.0591", 0.0787", 0.0984", 0.1181", 0.1575")

- Common Sizes: 4'x84', 4'x10'

- Characteristics: High corrosion resistance, excellent UV resistance, color consistency

- Processing: Perforation, cutting, bending

- Packaging: Cut into aluminum sheets or coils

White Color Coated Aluminum Coil for Printing

The white color coated aluminum coil for printing is a high-quality printing material with good flatness, corrosion resistance, and wear resistance.

This aluminum coil is widely used in the manufacturing of PS plates, CTP plates, and UV-CTP plates, meeting the requirements of various printing processes.

- Alloy: 1050, 1060, 1100, 3003

- Temper: H16, H18

- Thickness: 0.13-1.50mm (0.005"- 0.059")

- Width: 500-1600mm (19.685"-62.992")

- Length: Customizable

- Characteristics: Strong ink adhesion, extremely high flatness, no indentation, wear resistance

- Packaging: Cut into aluminum sheets or coils

Other apps

White color coated aluminum coil is also widely used in the packaging and furniture appliances fields.

It can be utilized in the manufacturing of food cans, lids, pull rings, food packaging sealed bags, as well as in air conditioners, washing machines, refrigerators, cabinet panels, and various types of digital electronic product casings.

Common issues with white color coated aluminum coil

White Color Coated Aluminum Coil Prices

The prices of white color coated aluminum coil are primarily influenced by various factors, including the grade of aluminum and aluminum alloy strip, width, thickness, and the production method of the blank material.

The pricing is also closely related to the coating quality and thickness, while packaging and transportation methods can also impact the price.

Can I order aluminum sheets in other colors?

Yes, you can. We have a variety of aluminum sheets in different colors in our inventory, including transparent, black, gold, blue, red, etc. This includes both anodized aluminum sheets and color-coated aluminum sheets.

If you have specific requirements, please contact us immediately.

Differences in Coatings for White Color Coated Aluminum Coil

- Epoxy: Known for outstanding strength and durability.

- Polyurethane: Renowned for its exceptional elasticity and wear resistance.

- Polyester: Exhibits good weather resistance, commonly used in outdoor structures and building materials.

- Silicone Modified Polyester: Possesses excellent corrosion resistance, often used in coatings for environments with high corrosion demands.

- Fluorocarbon: Features outstanding chemical corrosion resistance and climate stability, commonly used in high-end architectural exterior coatings.

Production Process of White Color Coated Aluminum Coil

- Aluminum Sheet Preparation: Select clean and flat aluminum coils or sheets as the base material.

- Pre-treatment: Chemically pre-treat the aluminum sheet.

- Primer Coating: Apply a primer coating on the aluminum base to enhance adhesion between the coating and the substrate.

- Color Coating: Use methods such as roller coating, spray coating, or other coating techniques to evenly apply colored paint on the primer layer.

- Curing: Pass the coated aluminum sheets through baking or other curing methods to form a solid, durable protective layer on the surface.

- Cold Rolling: Flatten the cured color-coated aluminum coil using a cold rolling machine.

- Inspection: Perform quality inspections, including visual inspection, coating adhesion testing, color consistency checks, and more.

- Packaging: Properly package qualified color-coated aluminum coils to prevent damage during transportation and storage.