Aluminum Curtain Wall Plate

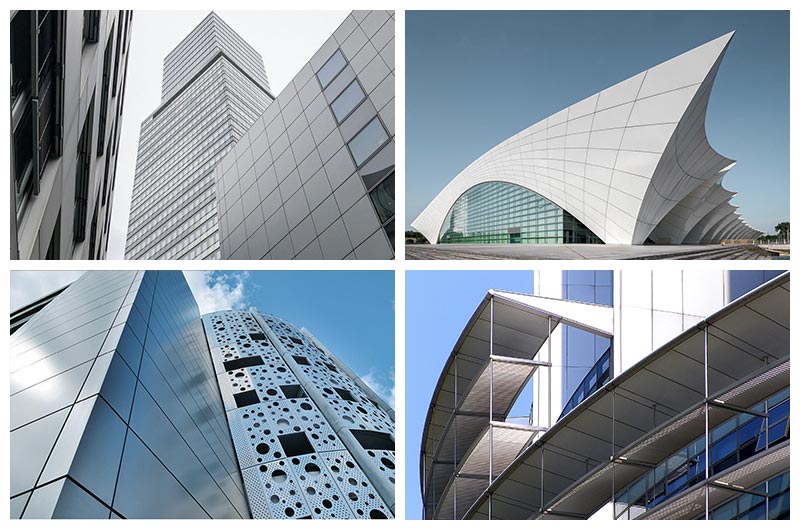

Aluminum alloy curtain wall panels, ideal for non-lighting walls, offer a distinctive texture, diverse colors, and compatibility with glass and stone. Firmly attached to aluminum alloy frames, they address detachment issues common in mosaic or glazed tile exterior walls.

Chalco offers popular aluminum alloy curtain wall plates, including 1050, 1060, 1100, 3003, and 5052, along with aluminum honeycomb plates, aluminum plastic composite plates and other composite curtain wall products. Services include PVDF/PE coatings and stamping and bending processing for curved and spherical plate surfaces. Comprehensive solutions for curtain wall panel projects can be provided by Chalco to meet the diverse needs of customers.

Specifications of Chalco aluminum curtain wall plate product

Alloy: 1050, 1060, 1100, 3003, 5052

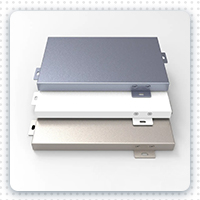

Conventional thickness: 1.0mm 1.5mm 2.0mm 2.5mm 3.0mm 4.0mm;(clip sheet≤1.2mm, single panel≥1.5mm).

Standard size: 4*8(1220mmx 2440mm)4*10(1220mm x 3050mm)

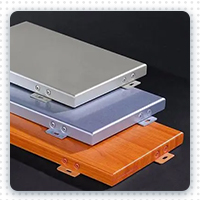

Surface processing: polished finish, transparent anodizing, powder coating, PVDF coating, wood grain finish, etc.

Surface coating: PVDF, PE etc.

Product standards: ASTM B209 ASME SB209 GB/T3880

Chalco aluminum curtain wall sheet plate product center

-

1050 1060 1100 1200 aluminum curtain wall sheet plateThe 1000 series aluminum plate is durable, lightweight, and easy to use; Mn element in the 1000 series aluminum alloy helps to form a protective oxide layer on the metal surface, improving corrosion resistance. It can be used for reflective curtain walls that require high flatness.

-

3003 3A21 3004 3105 aluminum curtain wall sheet plateThe 3000 series curtain wall aluminum plate has all the advantages of the 1000 series curtain wall plate, and has better welding performance. The addition of manganese element makes 3000 series aluminum plate have higher strength.

-

5005 5052 5754 5A02 aluminum curtain wall sheet plate5000 series aluminum alloy has moderate mechanical properties, good corrosion resistance and processability, making it the most widely used aluminum curtain wall alloy. The plate can be used in corrosive environments such as coastal cities and industrial environments.

-

Aluminum sheet for aluminum plastic composite boardCommonly used are AluPE and AluPU. The use of composite design can balance strength and workability. Chalco provides high-quality 1100, 3003 aluminum sheet for the production of aluminum plastic composite panels.

-

Aluminum honeycomb curtain wall plateThe honeycomb sandwich structure is made of aluminum alloy, and the surface is often covered with a certain thickness of solid aluminum plate. This design reduces the weight of the aluminum plate and improves its rigidity and strength.

-

Perforated curtain wall platePerfect for outdoor curtain walls or indoor suspended ceilings, Chalco offers customizable laser-carved punching plates with circular, square, or irregular grooves for noise reduction and decoration. The punching rate is critical for plate roughness and strength.

Chalco also has the ability to produce aluminum curtain walls in special shapes, such as curved, spherical, irregular, punched, corrugated, etc. And in order to provide better service to our customers, we can offer product processing services like coating plate, embossing, stamping, bending, stretching, etc. to make your project more convenient and cost-effective

Advantages of Chalco aluminum curtain wall plate

- Lightweight but highly rigid and consistent;

- Strong weather and chemical resistance;

- Good plasticity, flexible size and shape according to customer requirements;

- Easy to install and maintain, with a smooth surface and easy to clean;

- Comply with the fire rating standards for building materials such as EN 13501-1 A2, GB8624-2006 A2-s2 d0, ASTM E84-10a, EN 45545;

- Recyclable building materials are conducive to sustainable environmental development.

Coating of Chalco aluminum curtain wall plate

- Aluminum curtain wall plates are coated with PVDF or PE, applied through 2-3 rounds of spraying for a 30-40μm thickness. Surface treatment involves chromium plating followed by 2-4 layers of PVDF or PE coating.

- PVDF coatings boast exceptional corrosion and weather resistance, withstand acid rain, salt mist, and pollutants, and provide long-lasting color retention, non-powdering properties, and an extended service life.

- Chalco uses premium PVDF or PE coatings from PPG, DNT, AKZO, NIPPON, offering various colors. Customers can select directly or provide matching samples.

Choose Chalco as the supplier of aluminum curtain wall plate

Hot rolling project adopts the German Sigma (1+4) 4500mm hot continuous rolling production line, with a maximum width of 4000mm for the plate, a maximum width of 2650mm for the strip, and a minimum thickness of 1.8mm.

Using German Sigma six-high cold rolling mills, including a 2800mm single stand CVC mill and a 2800mm double stand CVC mill, our cold rolling project achieves aluminum plates up to 2650mm wide and 500mm thick, with stress relief to prevent deformation during cutting.

Chalco's production lines process complex shapes like curved and spherical surfaces on curtain wall panels through stamping, bending, and stretching. Pre-cut and formed aluminum plates reduce secondary processing costs, requiring only simple fixing at the construction site.

Chalco's high-quality plate has complete quality certification, complete products, large inventory, short delivery time, and discounted prices. Welcome to inquire and support price comparison.