Marine Grade Aluminum Plate

Chalco supplies 5000 series, 6000 series conventional marine aluminum plates, and military ship alloys such as 2024, 2124, 7075, and 7039. Value-added services include anodizing, chemical milling, polishing, drilling, cutting, welding, etc.

Chalco marine grade aluminum plate meets the standards of ABS, BV, CCS, DNV GL, KR, LR, NK, RINA and other ship classifications, and ensures price competitiveness. Whether it's luxury yachts, sightseeing boats, fishing boats, or patrol boats, Chalco can provide a wide range of application solutions.

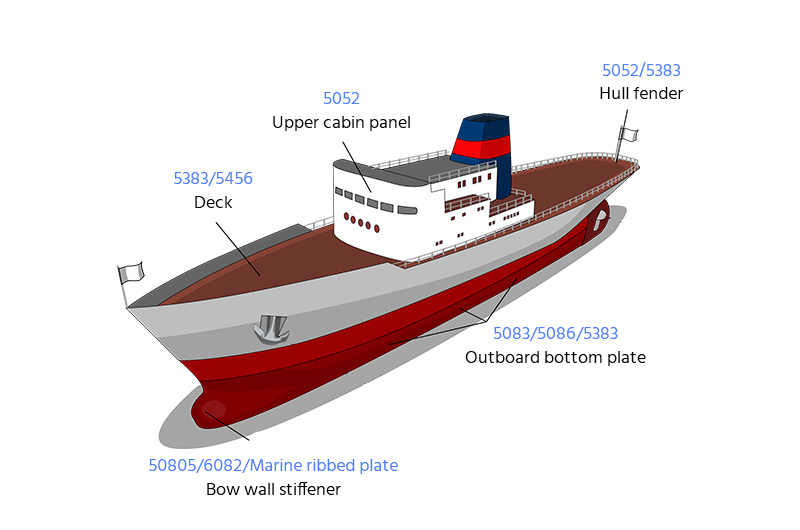

Aluminum plate for ship hull

The application of aluminum alloy in ship hulls is mainly in areas such as hull shells, decks, cabin panels, ship compartments, engine rooms, protective and insulation materials, and living facilities.

In addition to salt spray corrosion resistance, aluminum plates for ship hulls have high requirements for lightweight, in order to have better formability, reduce ship weight, and improve fuel efficiency.

-

5052 marine aluminum plate

Good corrosion resistance and formability, high fatigue strength...

O H14 H34

-

5083 marine aluminum plate

Highest strength among the non heat treated alloys, good weldability, corrosion resistance.

O H32

-

5086 marine aluminum plate

Welding and corrosion resistance are the same as 5083, with slightly lower strength.

O/H111 H112 H116 H32 H34

-

5383 marine aluminum plate

Board for the hull and bottom, hull deck, yacht shell, etc.

O/H111 H112 H116 H32 H34 H321

-

5454 marine aluminum plate

5000 series high-strength aluminum plate for hull structure, pressure vessels, pipelines.

O/H111 H112 H32 H34

-

5456 marine aluminum plate

Strength higher than 5083, with sensitivity to stress corrosion; The bottom and deck of the ship.

O H321

-

5754 marine aluminum plate

Excellent resistance to seawater; Hull pedals, ship side windows, container panels, etc.

O/H111 H112 H32 H34 etc.

-

5005 marine aluminum plate

Low density, good welding type; Horizontal skeleton structures for small fishing vessels and large vessels.

H22 H32 H24 H34 H26 H36

-

6061 marine aluminum plate

Partition structures and bolted and riveted structures that do not contact with seawater.

O T4 T451 T6 T651

-

2024 marine aluminum plate

Commonly used in manufacture military vessels with high-performance.

O T3 T4 F

-

2124 marine aluminum plate

High-strength aluminum plate, commonly used in the manufacturing of warships.

T3 T4 T351 T851

-

7075 marine aluminum plate

The strongest alloy among 7000 series. Commonly used for military vessels.

O H112 H12

-

Aluminum treat checkered plate

The diverse forms of raised patterns provide excellent anti slip performance.

-

Aluminum stiffened plates for ship hull

Made by cutting and welding aluminum plates; Improve load-bearing capacity.

-

Aluminum foam plate for cabin bulkhead

Aluminum foam plate has the characteristics of light weight, insulation, shock absorption, etc.

Aluminum plate for shipfitting

Aluminum shipfitting plates are mainly used in the auxiliary equipment sector, such as sails, oars, rudders, shipboards, installation plates for ship communication equipment, onboard storage equipment, cargo warehouses, and onboard energy auxiliary equipment such as solar panels and wind turbines.

Because the shipfitting has more complete shapes, so there are higher requirements for the processing performance and formability of aluminum plates.

-

5A01 marine aluminum plate

Good corrosion resistance and welding performance, strong impact resistance.

O H32 H111

-

5A05, 5A06 marine aluminum plate

Good welding performance, suitable for various welding methods.

O H112

-

6082 marine aluminum plate

The highest strength among 6000 series alloys, often referred to as structural alloys.

O T4 T451 T6 T651

-

1050 marine aluminum plate

Ship interior, cabin edge decorative strips and frames, porthole frames, etc.

O/H111 H12 H24

-

3033 marine aluminum plate

Ship interior, top and side panels of liquefied petroleum gas tanks.

O H112 H12

-

3203 marine aluminum plate

Good formability and corrosion resistance; Used for panels of liquefied petroleum gas tanks.

O H112 H12

Aluminum plates for marine and offshore engineering platforms

Aluminum alloy plates are also widely used in offshore buildings, mainly for the manufacturing of energy equipment such as offshore platform structures, oil well platforms, LNG cargo ships, offshore docks, and offshore wind and solar energy.

This has higher requirements for the strength, stability, weather resistance, and chemical corrosion resistance of aluminum plates.

-

3003 marine aluminum plate

LNG storage tanks and chemical containers, chemical equipment support structures.

-

3004 marine aluminum plate

Specific chemical storage tanks, offshore chemical equipment casings and supports.

-

7039 marine aluminum plate

Construction of offshore platform, supporting equipment, connectors and fasteners.

Chalco marine grade aluminum plate cooperation area

- Chalco provides high-strength, lightweight, and corrosion-resistant 5000 series aluminum plates and 2000, 7000 series high-strength warship aluminum plates.

- Chalco supplies 5454, 6061, and 6082 aluminum plates with strong structural performance, suitable for passenger and cargo ships.

- Chalco provides lightweight, easy processing and surface treated yacht aluminum plates to improve yacht speed, fuel efficiency, and aesthetics.

- Chalco supplies 5456, 6061 aluminum plates for fishing vessels, which have high strength and corrosion resistance, and can withstand corrosion in marine environments.

- Chalco provides chemical resistant and high-strength 3003, 3033, 3203, 5454 aluminum plates for the storage and transportation of petroleum and liquid cargo.

- Chalco supplies aluminum plates such as 5454 and 5083 for offshore buildings and offshore platforms, which adapt to extreme marine conditions, and have a long service life.

Chalco's marine grade aluminum sheet production capacity and product advantages

The hot rolling project adopts the German Sigma (1+4) 4500mm hot continuous rolling production line, with a maximum width of 4000mm for the plate, a maximum width of 2650mm for the strip, and a minimum thickness of 1.8mm.

The cold rolling project adopts the German Sigma six high cold rolling mill, a 2800mm single stand CVC cold rolling mill, and a 2800mm double stand CVC cold rolling mill. The aluminum plate has a maximum width of 2650mm and a thickness of up to 500mm, making it one of the few manufacturers that can produce ultra-wide and ultra-thick aluminum plates. Internal stress relief of the plate, no deformation during cutting.

Chalco can provide aluminum plate surface treatment, precision machining, cutting, stamping, deep drawing, embossing and other deep processing, providing customers with overall project solutions for aluminum plates used in tankers.

Chalco marine grade aluminum plate has complete quality certification, complete products, large inventory, short delivery time, and discounted prices. Welcome to inquire and support price comparison.