Aluminum Sheet Coil for Trailer

Lightweight and high-strength, with good corrosion resistance and processing performance, aluminum sheet coil has become the main material for processing trailer skins, side panels, and inner lining panels.

Chalco provides high-quality aluminum plates such as 3003, 5052, 5083, 6061 for aluminum trailers, with complete inventory of standard size aluminum plates. Special sizes can be customized for cutting, and there are multiple coating to choose from.

Specification of Chalco trailer sheet plate coil

Hot selling aluminum alloy: 3003, 5052, 6061, 5754, 5083, 5182

Thickness of the aluminum sheet: 0.024’’, 0.025’’, 0.030’’, 0.040’’, 0.050’’

Standard size: 48’’*96’’ 48’’*120’’ 48’’*110’’ 49’’*96’’ 4’*8’ 5’*8’

Application: teardrop trailer, cargo trailer, enclosed trailer, trailer truck, etc.

Product center of Chalco trailer aluminum plate

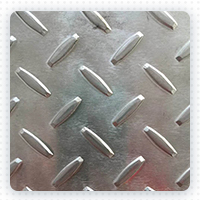

Diamond plate sheets for trailer floor

A concave convex pattern with diamond checkered and other shapes is usually used for trailer floor panels that require good traction performance to improve slip resistance and enhance durability.

Extra wide flat aluminum sheet coil for trailer skin

Chalco ultra wide aluminum plate can be 2650mm, which can effectively cover the surface of the trailer, provide good protection, and is suitable for covered trailer design.

White/Color coated aluminum sheets for trailers

Color-coated aluminum plates, available in white, black, yellow, matte, and other colors, are widely used in trailers, offering a visually appealing appearance while protecting the aluminum panels from environmental influences.s.

Mirror reflective aluminum sheets for trailers

Mirror reflective aluminum plate is an aluminum plate with high reflective performance, commonly used on the external surface of trailers to improve visibility and safety. Chalco mirror high reflection trailer board with a reflectivity of ≥ 86.

Chalco aluminum trailer sheet hot selling alloy

-

3003 aluminum trailer inner panel

Surface smoothness is high, which is not good for paint sticking. Mainly used for the lining of trailers.

-

5052 aluminum trailer skin panel

It has better painting performance, used for the outer skin of trailer and refrigerated trucks.

-

3105 color coated aluminum trailer plate

Good oxidation and coloring; surface treatment is usually carried out to increase weather resistance.

-

3004 aluminum trailer side panel

Good processability and weldability, which can meet bending and forming requirement of side plate.

-

5083 trailer aluminum plate

Good weldability and corrosion resistance, can be used as inner plate of hazardous cargo trailer.

-

6061 aluminum plate for trailer

Lightweight and strong, ideal for trailers to reduce weight and enhance fuel efficiency.

Paint-coating of Chalco trailer aluminum plate

- Chalco can produce ultra-wide color coated aluminum plate coil, the width for color coating plate can reach 2 meters and coating thickness is 5-25 μm;

- Chalco provides various coatings such as PVDF, HDP, PE, etc.;

- Aluminum plates need to undergo chemical pretreatment (cleaning) before color coating. Apply epoxy resin adhesive on the back, primer on the front, and then apply polyester (PE), PVDF or acrylic.

- Polyester coatings belong to a high weather resistance system, with high ductility and flexibility.

- PVDF coatings have better UV resistance, and 2-3 layers of PVDF coatings are suitable for various outdoor climates.

- Uniform coating; No black spots, resistant to fingerprints, anti-static, scratch resistant; The bent coating does not crack.

Colors of Chalco trailer plate coil

White trailer aluminum plate

Black trailer aluminum plate

Charcoal gray trailer plate

Red trailer aluminum plate

Blue trailer aluminum plate

Yellow trailer aluminum plate

Matte black trailer plate

Matte white trailer plate

Silver trailer aluminum plate

Choose Chalco as your trailer plate manufacture

- Chalco supplies 500 series and 6000 series aluminum sheet coils, suitable for trailer industry. The standard size inventory is large, and customized sizes can be cut according to requirements.

- Chalco color coated trailer sheet plate has complete colors and sizes, and the product surface is coated with film to avoid transportation, storage, and scratches.

- The hot rolling project adopts the German Sigma (1+4) 4500mm hot rolling production line, with a maximum width of 4000mm for the plate, a maximum width of 2650mm for the strip.

- The cold rolling project adopts the German Sigma six roll cold rolling mill, a 2800mm single stand CVC cold rolling mill, and a 2800mm double stand CVC cold rolling mill.

- Chalco has complete quality certification for high-quality trailer sheet, with a complete range of products, short delivery times, and discounted prices. Welcome to inquire and support price comparisons.