5 Production Steps of Color Coated Aluminum Coil Sheet

Updated : Jan. 9, 2024Color coated aluminum coil sheet refers to a product with a colored spray coating on the surface of an aluminum coil sheet. The purpose of coating treatment is primarily to achieve an aesthetic effect in areas such as construction, decoration, and home furnishing. Additionally, the coating process and thickness are directly related to the product quality and lifespan of color-coated aluminum coil sheet.

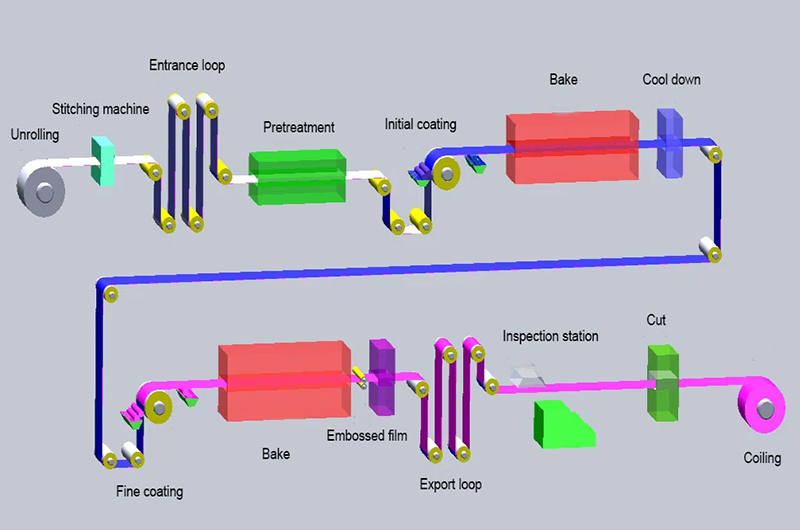

Chalco's production process for color coated aluminum coil sheet involves 5 steps, including aluminum coil pretreatment, coating application, drying and curing, cutting, inspection, and packaging.

Aluminum coil pretreatment

Aluminum coil pretreatment is the first step in the production of color-coated aluminum coils. Its main function is to clean the surface and remove scale and oil stains to ensure that the coating can firmly adhere to the surface of the aluminum coil.

Aluminum coil pretreatment is divided into two methods: mechanical cleaning and chemical cleaning.

- Mechanical cleaning mainly uses mechanical force and water flow to flush the surface of the aluminum coil to remove dirt and oxide scale on the surface.

- Chemical cleaning uses chemical methods such as pickling or alkali cleaning to remove surface oxide scale and oil stains.

After the aluminum coil pretreatment is completed, it needs to be washed and dried to ensure that the surface of the aluminum coil is clean and pollution-free.

Paint coating

Paint coating is the core link in the production of color-coated aluminum coils. Its quality directly affects the performance and appearance of color-coated aluminum coils.

Paint coating mainly includes three links: primer coating, powder spraying and topcoat coating..

- Primer coating is mainly to improve the adhesion and anti-corrosion properties of the coating.

- Powder spraying is to spray a layer of powder coating on the surface of the color-coated aluminum coil and then dry it at high temperature to form a hard and wear-resistant coating.

- Topcoat coating is to increase the aesthetics and weather resistance of color-coated aluminum coils.

Drying and curing

Drying and curing is an important step in the production of color-coated aluminum coils. Its main function is to evaporate the solvent in the coating and solidify the coating into a film. Drying and curing are divided into two methods: natural drying and oven drying..

- Natural drying is to expose the paint surface to the air and use natural oxidation reactions to gradually solidify the coating.

- Drying uses heating methods such as hot air or infrared rays to evaporate the solvent in the paint and quickly solidify the coating.

Cutting

Cutting is an important process in the production of color-coated aluminum coils. Its main function is to cut color-coated aluminum coils into plates or coils of different sizes. The main cutting methods include shearing, curling and trimming.

- Shearing is to use a shearing machine to cut the color-coated aluminum coil into sheets or coils of the required length along a straight line.

- Curling involves rolling color-coated aluminum coils into different shapes and sizes.

- Trimming is to cut the edges of color-coated aluminum coils into different shapes and sizes.

Inspection and packaging

Inspection and packaging are the last process in the production of color-coated aluminum coils. Its main function is to conduct quality inspection and packaging of color-coated aluminum coils to ensure that the products meet standards and requirements.

Inspection mainly includes appearance inspection, dimensional inspection, coating thickness inspection, etc.

Packaging is to pack the color-coated aluminum coils according to customer requirements for easy transportation and storage.