10 Types of Aluminum Sheets After Surface Treatment

Updated : Dec. 13, 2023Surface treatment refers to the mechanical and chemical methods applied to alter the appearance and properties of the aluminum sheet surface.

The goal is to enhance corrosion resistance, wear resistance, conductivity, and other characteristics, thereby extending its lifespan and improving the overall aesthetics of the product.

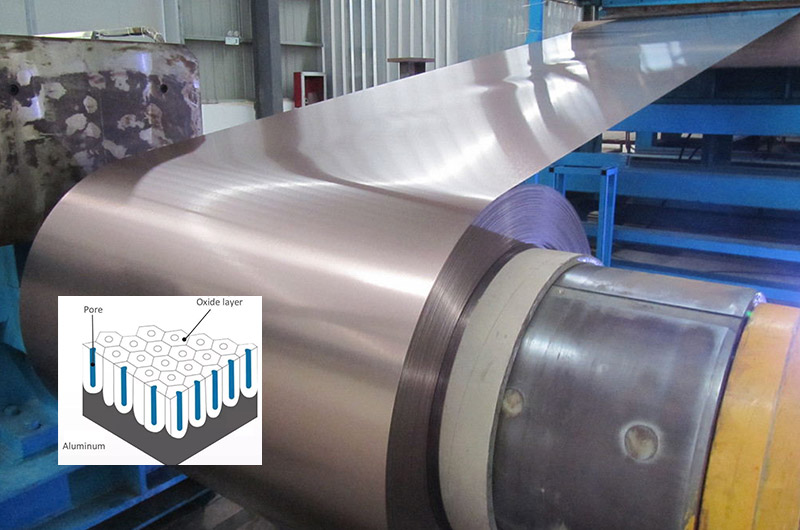

Anodized aluminum sheet

There are two main types of aluminum anodization: regular electrolytic anodizing and hard anodizing.

Regular anodized aluminum sheets involve placing the aluminum sheet in a specific electrolyte solution (such as sulfuric acid, chromic acid, oxalic acid, etc.) as the anode.

Through the principles of electrochemistry and under specific conditions with an applied electric current, a layer of aluminum oxide film forms on the surface. The thickness of this oxide film typically ranges from 5 to 20 micrometers.

Aluminum sheets can also undergo hard anodizing, resulting in significantly improved wear resistance, heat resistance, and electrical insulation properties.

The oxide film produced through hard anodizing can reach thicknesses of 60 to 200 micrometers, with surface hardness ranging from 400 to 1200HV.

However, in terms of coloring, hard anodizing may not achieve the same results as regular anodizing. Hard anodizing is an essential surface treatment process for products in aerospace, aviation, automotive cylinders, transmissions, and other related industries.

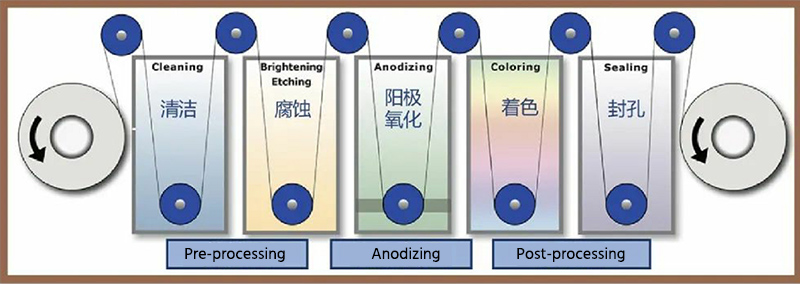

Anodized aluminum sheet process

Monochrome and gradient anodized aluminum sheet process

Polishing/Sandblasting/Brushing → Degreasing → Anodizing → Neutralization → Dyeing → Sealing → Drying

Two-color anodized aluminum sheet process

Polishing/Sandblasting/Brushing → Degreasing → Masking → Anodizing 1 → Anodizing 2 → Sealing → Drying

Performance and characteristics of anodized aluminum sheet

After anodization, aluminum sheets exhibit strong decorative and weather-resistant properties, enhanced hardness, wear resistance, good heat resistance, and excellent insulation.

Moreover, with low maintenance costs in the long run, anodization is the most commonly used surface treatment method for aluminum sheets.

Alloys suitable for anodized aluminum sheet

1050, 1060, 1100, 2024, 3003, 3004, 3005, 5005, 5052, 5083, 5754, 6061, 6063, 6082, 7075

Applications of anodized aluminum sheet

- Aircraft and aerospace applications for skin and wings.

- Automotive industry for oil cylinders, transmission components, body panels, roofs, doors, and wheels.

- Architectural decoration, including facades, curtain walls, ceilings, partitions, and handrails.

- Electronic components such as integrated circuits, capacitors, resistors, and semiconductors.

- Furniture and household appliances.

- Medical instruments.

Aluminium checker plate

Aluminum tread plate, sometimes also referred to as aluminum diamond plate, aluminum flooring, or aluminum tread, is a type of patterned plate widely used as non-slip flooring in commercial and industrial floor applications. It is also utilized in vehicles such as ambulances, fire trucks, and trucks.

Patterned aluminum plate is a type of aluminum rolled plate. One side features raised rhombic or linear patterns, while the other side is smooth.

Pattern design and configuration → Ingredient preparation → Surface cleaning → Embossing (stamping, rolling) → Surface coating → Cutting

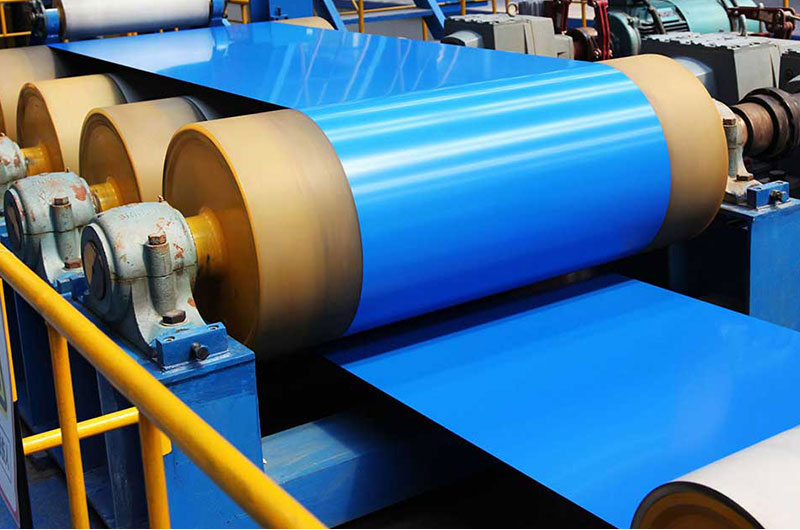

Coated aluminium sheets

Color-coated aluminum plate is a type of aluminum plate with a surface coated with an organic paint, typically polyester, polyurethane, polyimide, etc., which is then heated and cured to form a protective and decorative layer.

The coating can enhance the corrosion resistance and wear resistance of the aluminum plate while altering its surface color and decorative effects. Coated aluminum surfaces can have matte, semi-gloss, and high-gloss finishes.

Advantages of color-coated aluminum plate

Color-coated aluminum plate combines the advantages of aluminum and organic materials. It possesses the high mechanical strength, good toughness, and easy processing of aluminum, as well as the excellent coloring, decoration, and corrosion resistance of organic polymer coating materials.

It can be easily subjected to processes like bending, deep drawing, welding, resulting in practical, easy-to-process, and durable products.

Alloys applicable to color-coated aluminum plate and their applications

1050, 1100 color-coated aluminum plate

Strong processing performance and corrosion resistance, commonly used in interior decoration and advertising boards.

3003, 3004 color-coated aluminum plate

Strong corrosion resistance and weldability, commonly used in building exteriors and roofs.

5052, 5754 color-coated aluminum plate

High tensile strength and strong corrosion resistance, commonly used in automotive bodies, railway vehicles, and ships.

6061, 6063 color-coated aluminum plate

Strong mechanical properties and cutting processing, commonly used in construction and decoration.

7075 color-coated aluminum plate

High strength and high corrosion resistance, commonly used in aerospace and military applications.

Color-coated aluminum plate can also be applied in power cables, food packaging, furniture manufacturing, sports facilities, and other fields.

Sandblasted aluminum plate

Process of sandblasted aluminum plate

Sandblasting is a process that uses purified compressed air to spray dry sand or other abrasive particles onto the surface of aluminum products. This process utilizes the impact of high-speed sand flow to clean and roughen the metal surface.

Commonly used abrasives in sandblasting include diamond sand, aluminum oxide particles, glass beads, and stainless steel sand. The use of steel and iron abrasives is generally prohibited because they can embed into the aluminum matrix, causing galvanic corrosion.

Advantages of sandblasted aluminum plate

- Prepares for other surface treatment processes.

- Improves the mechanical properties of aluminum parts.

- Cleans tiny burrs on the aluminum plate surface and makes the surface smoother.

- Removes residual impurities from pre-treatment, enhances the cleanliness of the aluminum plate, making it more aesthetically pleasing.

- Solves the problem of metal reflection; some aluminum products strictly prohibit reflection.

Alloys applicable to sandblasted aluminum

1100,3003,5052,6061

Applications of sandblasted aluminum plate

- 3C communication components

- Textile machinery parts

- Aerospace precision parts

- Medical device accessories, surgical instruments

- TV shell or middle frame

- Cabinet material

In countries like Russia, Ukraine, Israel, etc., sandblasting is commonly used in the treatment of cabinet materials.

Brushed aluminum sheets

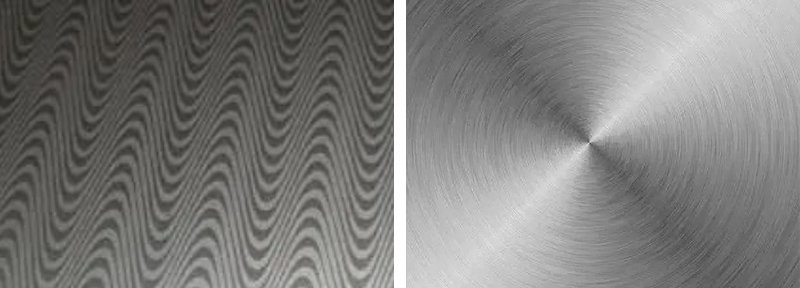

Brushed Aluminum Plate is manufactured through various brushing techniques. Depending on decorative requirements, it can be produced in several patterns such as straight lines, random lines, threads, waves, and spirals.

The process of brushed aluminum plate

Linear brushing

Refers to the process of mechanically rubbing the surface of the aluminum plate to create straight lines. It serves a dual purpose of removing scratches on the aluminum plate surface and decorating the aluminum plate. The linear brushing process can be continuous or intermittent.

Random brushing

It is a type of matte finish obtained by moving the aluminum plate back and forth, left and right, under the high-speed rotation of a copper wire brush.

This process results in irregular and indistinct patterns. It demands high surface requirements for aluminum or aluminum alloy plates.

Corrugated brushing

Corrugations are typically created on a brushing or rubbing machine. By utilizing the axial movement of the upper grinding rollers, a wavy pattern is achieved through brushing the surface of aluminum or aluminum alloy plates.

Spiral brushing

Spiral brushing, also known as rotary brushing, involves using cylindrical felt or abrasive nylon wheels mounted on a drilling machine. Polishing paste, mixed with kerosene, is applied during the rotational polishing process on the surface of aluminum or aluminum alloy plates. This method is commonly used for decorative processing of round signs and small decorative dials.

Threaded brushing

Threaded brushing involves using a small motor with a circular felt mounted on a shaft. The motor is fixed on a tabletop at an angle of approximately 60 degrees to the edge of the table.

Additionally, a drag plate with a fixed aluminum plate for pressing is used, and a polyester film with a straight edge is attached to the drag plate to limit the spiral pitch. By utilizing the rotation of the felt and the linear movement of the drag plate, consistent-width threaded patterns are created on the surface of the aluminum plate.

Cross-Hatch brushing

Cross-hatch brushing is typically processed using a polishing machine or brushing machine. The aluminum plate passes through two sets of rollers, causing a cross-hatch pattern to be pressed onto the surface of the aluminum plate.

Advantages of brushed aluminum plate

The surface treatment process of brushed aluminum single panel not only removes fine scratches on the surface of the aluminum plate but also, when combined with different texture effects in design, serves various decorative purposes.

Brushed aluminum alloy surfaces exhibit high smoothness, are easy to clean, possess excellent decorative properties, and offer better processability for more challenging machining and forging. Additionally, they have superior corrosion resistance and strength, making them suitable for use in harsh environments.

In some retro architectural design styles, using brushed aluminum single panels with this special process as curtain wall materials can bring a stylish appearance and a matte metal texture, often creating a strong visual impact and making the overall architectural design style more magnificent and unique.

Applicable alloys for brushed aluminum plate

1050,1060,1100,3003,3004,5052,5005,5083,6061,6063,7075

Applications of brushed aluminum plate

Brushed aluminum plates can be used as decorative materials for curtain walls, ceilings, partitions, etc. They are also suitable for metal box packaging in everyday life, such as furniture, home appliances, and electronic products.

5052 brushed aluminum plate is applied in the outer panel decoration of appliances, especially in the electronics industry, including the extensive use of brushed aluminum plates in Apple products.

3003 and 3004 are commonly used in air conditioners, refrigerators, and other electrical appliances.

Mirror aluminum plate

Mirror aluminum plate is a common material in aluminum single panels. It generally refers to aluminum plates that have been processed through rolling, polishing, and other methods to achieve a mirror effect on the surface. Internationally, mirror aluminum plates are usually produced using the rolling method, resulting in coils or sheets.

Production process of mirror aluminum plate

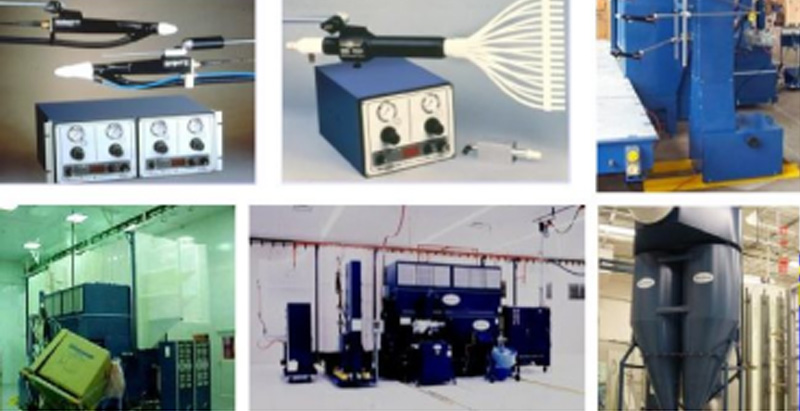

China Aluminum Industry specializes in producing polished mirror aluminum plates. The surface polishing process of aluminum plates includes three main methods: mechanical polishing, electrolytic polishing, and chemical polishing.

Mechanical polishing

Mechanical polishing involves grinding between the polishing wheel coated with polishing paste and the part grinding stone to improve the surface smoothness of metal products.

Chemical polishing

Chemical polishing equipment is simple, energy-saving, efficient, and cost-effective. It eliminates the cumbersome steps of hanging, and it is not limited by the shape and size of parts.

Especially for small-sized and complex-shaped parts where mechanical polishing is not feasible, chemical polishing can achieve a uniform, bright surface.

Electrolytic polishing

Electrolytic polishing uses a direct current power supply with a voltage of about 25-30V. The workpiece to be polished must be placed on the anode and have good conductivity.

Advantages of mirror aluminum plate

- Environmentally friendly, changes the optical quality and durability of internal space with brightness and transparency

- Easy to process and install

- Enhances spatial perception and interior decoration

- Hard surface, good corrosion resistance

- Smooth surface, easy to clean

- Flame retardant, wear-resistant, waterproof, moisture-resistant, soundproof, heat-insulating, corrosion-resistant

- Anti-interference, excellent electromagnetic wave shielding, good heat dissipation performance

Applicable alloys and applications of mirror aluminum plate

1050, 1060, 1070, 1080, 1085, 1090 mirror aluminum plate

Simple production process, low cost. Suitable for architectural decoration, lighting fixtures, solar reflectors, and electronic product casings.

3003, 3004, 3005, 3104, 3105 mirror aluminum plate

High alloy strength, excellent bending ability. Suitable for lighting reflectors, cosmetics industry, architectural coating materials and room decoration, aluminum ceilings, wall panels, cabinet panels.

5454, 5182, 5183, 5754 mirror aluminum plate

Higher strength and tensile strength. Suitable for pressure vessels, marine facilities, pipelines, automobile wheels, and tanks.

Painted aluminum sheets

Aluminum sheets can have their color changed through the process of painting. In current aluminum sheet painting processes, the common and widely used methods are fluorocarbon coating (PVDF coating) and powder coating.

Both of these fall under the category of electrostatic spraying processes, with the difference being that powder coating uses solid powder coatings, while fluorocarbon coating utilizes fluorocarbon coatings mixed with aluminum powder.

Fluorocarbon coating vs. Powder coating for painted aluminum sheets

Powder coating for painted aluminum sheets

Electrostatic powder coating is a method where a high-quality powder coating is first sprayed onto the surface of the aluminum sheet. Subsequently, it undergoes high-temperature heating, leveling, and curing to form a surface coating layer.

Characteristics of powder coating

Its coating thickness can be controlled, and a coating with a thickness of 50 to 300 micrometers can be obtained in one coating. It has good corrosion resistance and decorative functionality, making it more energy-efficient, environmentally friendly, and easy to achieve automation with a high coating utilization rate.

However, it is susceptible to sunlight and ultraviolet radiation, and prolonged exposure may result in noticeable color differences.

Cost of powder coating

The price of powder-coated sheet metal is generally cheaper than fluorocarbon coating.

Applicable alloys for powder coating

1100,3003,5005,5052,6061

Applications of powder coating

Automobile carriages, frames, daily cosmetic packaging, electronic casings, industrial equipment, pipes and fittings, home building materials, furniture, wall panels, ceilings, partitions.

Fluorocarbon coating for painted aluminum sheets

Fluorocarbon coating is one of the most widely used surface treatment processes for aluminum sheets. Its main raw material is PVDF resin (fluorine content not less than 70%). PVDF in the coating has characteristics such as toughness, low friction coefficient, corrosion resistance, aging resistance, weather resistance, and radiation resistance.

Characteristics of fluorocarbon coating

Fluorocarbon coating has higher wear resistance and adhesion. It exhibits excellent performance in terms of fading resistance, anti-frosting, corrosion resistance, UV resistance, and crack resistance.

It is also maintenance-free, self-cleaning, and the coating can be recycled during production, giving the aluminum sheet a lifespan of up to twenty years.

Cost of fluorocarbon coating

The price of fluorocarbon coatings is about RMB 10,000/ton more expensive than powder coatings.

Applicable alloys for fluorocarbon coating

1100,3003,5005,5052,6061

Applications of fluorocarbon coating

Architectural profiles, doors and windows, curtain wall panels, external surfaces of transportation vehicles, electronic products such as mobile phones, computer casings, and chemical equipment.

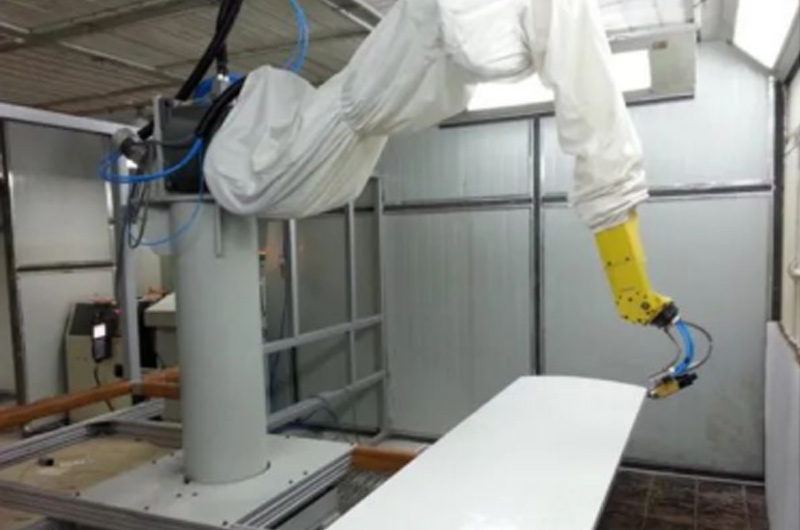

Process flow for painted aluminum sheets

1. Degreasing and deoiling of aluminum sheets

2. Chemical cleaning

3. Water rinsing

4. High-temperature drying

5. Primer coating

6. Topcoat coating

7. Baking (180℃-205℃)

8. Film curing

9. Quality inspection

10. Packaging

The aluminum veneer must undergo pretreatment before spraying to improve the adhesion and oxidation resistance between the coating and the aluminum surface, extend the service life of the paint film, and ensure that the coating does not peel off.

Before spraying on the aluminum veneer, the surface of the aluminum sheet needs to undergo degreasing, cleaning, and chemical treatment to produce a chromate film.

Electrophoretic aluminum plate

Colored electrophoretic coating on aluminum plate is a novel surface treatment process. It uses an electrochemical method to deposit colloid particles of organic resin on the components, forming a transparent or various colored organic coating.

Depending on the charged state of the resin particles in the electrophoretic paint after ionization, it can be divided into anodic electrophoresis (resin particles ionize into negative ions) and cathodic electrophoresis (resin particles ionize into positive ions).

Electrophoretic aluminum plate process

Pre-cleaning → Loading → Degreasing → Water Rinse → Derusting → Water Rinse → Neutralization → Water Rinse → Phosphating → Water Rinse → Passivation → Electrophoretic Coating → Tank Cleaning → Ultrafiltration Rinse → Drying → Unloading

Advantages of electrophoretic aluminum plate

- Rich color options with strong color fastness.

- Processing in a liquid environment allows for surface treatment of complex structures.

- High precision control of coating thickness.

- Mature and efficient process suitable for mass production.

- High degree of automation, labor-saving, and suitable for large-scale industrial production.

- Excellent corrosion resistance (able to pass neutral salt spray test for over 400 hours).

- Strong adhesion to the base metal, allowing various mechanical processing.

- Minimal environmental pollution and harm.

Applicable alloys for electrophoretic aluminum plate

1100,3003,5005,6061

Applications of electrophoretic aluminum plate

- Automotive shells and various components

- Bicycle handlebars and accessories

- Aluminum building materials, curtain walls

- Various daily hardware accessories

- Furniture

- Art and crafts

Plating aluminum sheet

Plating aluminum sheet is a process that uses electrolysis to deposit a metal film on the surface of metal, preventing corrosion and enhancing properties such as wear resistance, conductivity, reflectivity, and aesthetics.

Process of plating aluminum sheet

The aluminum and aluminum alloy plating process consists of three parts: pre-plating treatment, electroplating, and post-plating treatment.

Pre-plating treatment is the most crucial process affecting the quality of electroplated products. Its main purpose is to remove grease, naturally form an oxide film, and eliminate other impurities on the surface of aluminum and aluminum alloy.

Degreasing → Alkaline Etching → Activation → Zinc Replacement → Activation → Electroplating (such as nickel, zinc, copper, etc.) → Chromium Plating or Passivation → Drying

Advantages of plating aluminum sheet

- High gloss of the coating, providing a high-quality metallic appearance.

- Relatively low cost.

- Increased surface hardness and wear resistance.

- Reduced friction coefficient, improved lubrication.

- Improved surface conductivity.

- Enhanced corrosion resistance (including in combination with other metals).

- Easy to weld.

- Improved adhesion during hot pressing with rubber.

- Increased reflectivity.

- Restoration of dimensional tolerances.

Applicable alloys for plating aluminum sheet

1100,3003,5052,6061,7075

Types of plating and applications for plating aluminum sheet

Black plating

Used in optical electronics and medical instruments, such as black zinc and black nickel.

Gold, silver plating

Best conductors for electronic products, enhancing both conductivity and decoration. However, these are relatively expensive and are typically used in electronic products like high-precision wire terminals.

Copper, NICKEL, CHROMIUM

The most popular mixed plating in modern scientific fields, widely used in sports equipment, lighting, and most electronic industries due to its cost-effectiveness, decorative properties, and corrosion resistance.

White tin-copper

Developed in the 1970s-1980s for environmentally friendly plating, characterized by a bright white color and is the preferred choice in the jewelry industry.

Bronze

Lead-tin-copper can mimic gold, making it a good decorative plating. However, copper's resistance to discoloration is relatively poor, leading to slow development.

Zinc plating

The zinc-plated layer appears bluish-white, easily soluble in acids and alkalis. Zinc is chosen as a protective layer for aluminum sheets used in industrial atmospheres and marine atmospheres.

Hard chromium

Chromium-plated layers deposited under certain conditions have high hardness and wear resistance, reaching a hardness of HV900-1200 kg/mm.

Chromium is the hardest coating commonly used, enhancing wear resistance and prolonging the lifespan of parts. Therefore, this plating is indispensable for cylinders, hydraulic systems, and transmission systems.

Perforated aluminum sheet

Perforated aluminum sheet refers to various perforated aluminum sheets created by professional CNC equipment punching holes in aluminum sheets.

After perforation, the edges are folded using a bending machine, and the appearance is treated with fluorocarbon or powder coating to prevent natural oxidation of the aluminum sheet.

Alternatively, for aesthetic purposes, various colors can be applied according to customer requirements, creating a colorful appearance. These perforated aluminum sheets are installed on buildings, serving a decorative and beautifying purpose.

Perforated aluminum sheets are divided into regular perforated sheets and irregular perforated sheets. Regular perforated sheets have consistent hole diameters and spacing, making them frequently used and repurchased by customers. Irregular perforated sheets, on the other hand, have varying hole diameters and spacing, presenting images such as landscapes and figures through the irregular arrangement of holes.

Craftsmanship of perforated aluminum sheet

Common perforation methods include CNC punching, stamping, and laser perforation.

CNC punching or laser cutting is the ideal choice for creating custom perforations and patterns. It allows for the selection of various hole sizes and unique shapes.

Custom perforation patterns and shapes, produced using precision machines and other advanced manufacturing techniques, can achieve an infinite variety of folded and perforated panel designs.

Applicable alloys for perforated aluminum sheet

1060,1100,3003,5052

Advantages of perforated aluminum sheet

- As an architectural skin, perforated aluminum sheet can directly or indirectly impact the thermal performance of buildings in terms of ventilation, shading, and daylighting.

- Lightweight with high strength.

- Corrosion-resistant, highly malleable, durable, and easy to process.

- Recyclable, environmentally friendly, and energy-efficient.

- Simple installation and maintenance, saving construction costs.

- Good bending strength and wind pressure resistance.

- Wide field of vision, aesthetically pleasing, and visually impactful.

Applications of perforated aluminum sheet

- Architectural decoration, including curtain walls, interior decoration, ceilings, stairs, and balcony railings

- Sunshades

- Air diffusers

- Gas and liquid filters

- Machinery protective covers

- Flooring