5052 Color Coated Aluminum Coil Sheet

Chalco provides 5052 color-coated aluminum coils that meet the needs of various industries. It has a 2700mm ultra-wide pre-rolled line to produce double-sided color pre-rolled products, especially ultra-wide double-sided color-coated aluminum coils within 2630mm. It is widely supplied and is mainly used Used in aluminum-plastic panels, industrial factory floors and walls, aluminum shutters, electronic appliances, sinks, etc..

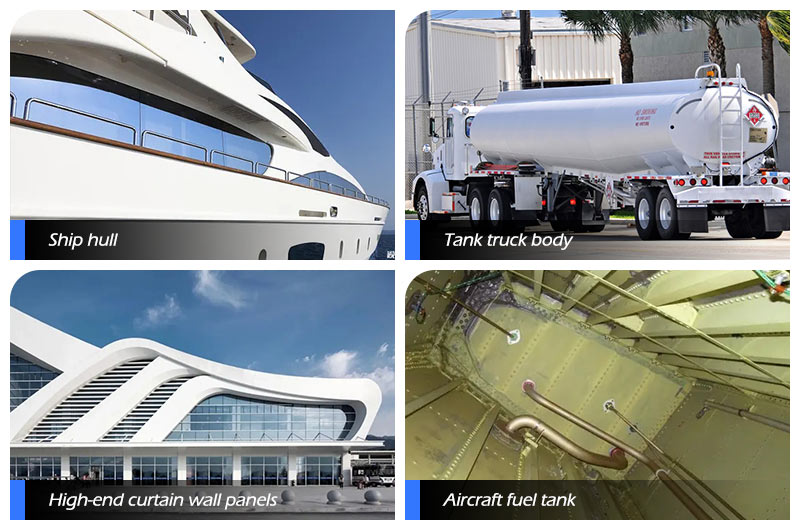

Chalco 5052 color-coated aluminum coil is made of 5052 aluminum base material. The main element is magnesium. It is corrosion-resistant and suitable for marine environment. It is mainly used for ship hulls, ship decks, etc.

Specifications of Chalco 5052 color coated aluminum sheet coil

Alloy: 5052

Temper: H42 H44 H46

Color: RAL color, or press to confirm sample (customized)

Surface: Textures such as wood grain, stone grain, mesh, embossing, camouflage, metal etc.

Coating material: PE,PVDF, EPOXY

Painting method: Powder coating, spray coating, roller coating

Coating thickness: Single coating (4μm-20 μm); double coating (25μm-28 μm); 3 coatings (35μm-38μm)

Hot Size: 4×6, 4x 8, 4×10 foot, etc or Customized

Advantages of Chalco 5052 color-coated aluminum coil products

- 5052 color-coated aluminum coils contain magnesium and chromium, making them highly corrosion-resistant and especially suitable for marine environments.

- 5052 color-coated aluminum coils have low density and light weight, so they are easy to handle and transport and reduce costs.

- The base material of 5052 color-coated aluminum coils is magnesium-aluminum alloy, which has better corrosion resistance. In addition, it can last for years without rotting or fading through PE or PVDF coating.

- 5052 color-coated aluminum coils are available in a variety of colors and textures. Common wood grains, stone grains, metal textures, etc. can be customized.

- Chalco 5052 color-coated aluminum coils use high-quality aluminum substrates and coating materials. The coating materials are all purchased from PPG or Nippon companies, and the quality is guaranteed.

Chalco 5052 color-coated aluminum coil application cooperation areas

- Hull, ship deck, shipping container

- Body panels, fuel tanks, chassis, tanker bodies

- Aluminum plastic panels, nameplates, billboards, traffic signs, car license plates

- High-end curtain wall panels, subway station siding and other high-end architectural decoration

- Aircraft parts, fuel tanks

- Shutters, doors

- Computers, mobile phones, TVs, audio casings

FAQ about Chalco 5052 color coated aluminum sheet coil purchase

How to choose 5052 color coated aluminum coil manufacturers and suppliers?

Chalco's high-quality 5052 color-coated aluminum coils have complete quality certification, complete products, huge inventory, and short delivery time. The sheet size, color, coating, texture, etc. can be customized according to customer needs. Welcome to inquire and order.

Where can I buy 5052 color-coated aluminum coils at a good price?

The cost of color-coated aluminum coils depends on the type, thickness and size of the sheet, as well as the type of coating material required. With its complete set of color-coated aluminum coil production lines, Chalco can ensure the source production and sales of color-coated aluminum coils at very competitive prices.

What are the coating materials for color-coated aluminum coils?

Chalco color-coated aluminum coils have multiple coating materials. Commonly used coating materials include PE polyester coating and PVDF fluorocarbon coating. For more information, please click to view.

Production process of color-coated aluminum coils

The production process of Chalco color-coated aluminum coils has five steps, including aluminum coil pretreatment, paint application, drying and curing, cutting, inspection and packaging. For details, please refer to the 5 production steps of color-coated aluminum coils

Is Chalco a factory?

Chalco is a manufacturer of deadly colored aluminum coils. The coating adopts an internationally advanced precision three-mix reverse mixing machine. Precision coating is carried out in a closed and dust-free state, so that the thickness of the coating film and the appearance quality of the coating are improved. Control to ensure the quality of products delivered to customers.

How to pack Chalco color picture aluminum coils?

Pack and label as per regulations and customer requirements to avoid any possible damage during storage or transportation.