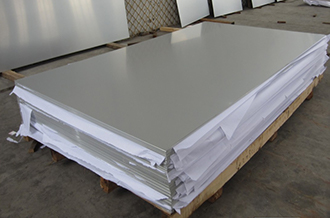

5052 H112 Aluminum Plate

5052 aluminum is a non heat treatable alloy with excellent precision machining quality. Magnesium endows 5052 alloy with stronger workability, strength, weldability, and corrosion resistance, especially for saltwater and marine atmospheres. 5052 aluminum plate has the best welding characteristics among all aluminum alloys and can be easily welded using the most common techniques.

H112 semi hard 5052 aluminum plate has higher tensile strength than soft and annealed states, balanced processing performance, and better cutting performance. After being treated in the H112 temper, its crystalline structure becomes more stable, and its corrosion resistance in harsh environments is further improved.

Chalco 5052 H112 aluminum plate stock size

| Product | Thickness/in | Thickness/mm | Width*Length/mm |

|---|---|---|---|

| ASTM B209 .040t 5052 H112 aluminum plate | 0.040 | 1 | 1250*2500 |

| ASTM B209 .050t 5052 H112 aluminum plate | 0.050 | 1.2 | 1250*2500 |

| ASTM B209 .060t 5052 H112 aluminum plate | 0.060 | 1.5 | 1250*2500 |

| ASTM B209 .063t 5052 H112 aluminum plate | 0.063 | 1.6 | 1250*2500 |

| ASTM B209 .080t 5052 H112 aluminum plate | 0.080 | 2 | 1250*2500 |

| ASTM B209 .100t 5052 H112 aluminum plate | 0.100 | 2.5 | 1250*2500 |

| ASTM B209 .125t 5052 H112 aluminum plate | 0.125 | 3 | 1250*2500 |

| ASTM B209 .160t 5052 H112 aluminum plate | 0.160 | 4 | 1250*2500 |

| ASTM B209 .200t 5052 H112 aluminum plate | 0.200 | 5 | 1250*2500 |

| ASTM B209 .250t 5052 H112 aluminum plate | 0.250 | 6 | 1250*2500 |

| ASTM B209 .313t 5052 H112 aluminum plate | 0.313 | 8 | 1500*3000 |

| ASTM B209 .375t 5052 H112 aluminum plate | 0.375 | 10 | 1500*3000 |

| ASTM B209 .500t 5052 H112 aluminum plate | 0.500 | 12 | 1500*3000 |

| ASTM B209 .563t 5052 H112 aluminum plate | 0.563 | 14 | 1500*3000 |

| ASTM B209 .600t 5052 H112 aluminum plate | 0.600 | 15 | 1500*3000 |

| ASTM B209 .625t 5052 H112 aluminum plate | 0.625 | 16 | 1500*3000 |

| ASTM B209 .700t 5052 H112 aluminum plate | 0.700 | 18 | 1500*3000 |

| ASTM B209 .750t 5052 H112 aluminum plate | 0.750 | 20 | 1500*3000 |

| ASTM B209 .875t 5052 H112 aluminum plate | 0.875 | 22 | 1500*3000 |

| ASTM B209 1.000t 5052 H112 aluminum plate | 1.000 | 25 | 1500*3000 |

| ASTM B209 1.125t 5052 H112 aluminum plate | 1.125 | 28 | 1500*3000 |

| ASTM B209 1.188t 5052 H112 aluminum plate | 1.188 | 30 | 1500*3000 |

| ASTM B209 1.250t 5052 H112 aluminum plate | 1.250 | 32 | 1500*3000 |

| ASTM B209 1.375t 5052 H112 aluminum plate | 1.375 | 35 | 1500*3000 |

| ASTM B209 1.500t 5052 H112 aluminum plate | 1.500 | 40 | 1500*3000 |

| ASTM B209 1.750t 5052 H112 aluminum plate | 1.750 | 45 | 1500*3000 |

| ASTM B209 2.000t 5052 H112 aluminum plate | 2.000 | 50 | 1500*3000 |

| ASTM B209 2.175t 5052 H112 aluminum plate | 2.175 | 55 | 1500*3000 |

| ASTM B209 2.250t 5052 H112 aluminum plate | 2.250 | 60 | 1500*3000 |

| ASTM B209 2.500t 5052 H112 aluminum plate | 2.500 | 65 | 1500*3000 |

| ASTM B209 2.750t 5052 H112 aluminum plate | 2.750 | 70 | 1500*3000 |

| ASTM B209 3.000t 5052 H112 aluminum plate | 3.000 | 75 | 1500*3000 |

| ASTM B209 3.150t 5052 H112 aluminum plate | 3.150 | 80 | 1500*3000 |

| ASTM B209 3.150t 5052 H112 aluminum plate | 3.150 | 80 | 1500*4000 |

| ASTM B209 3.375t 5052 H112 aluminum plate | 3.375 | 85 | 1500*3000 |

| ASTM B209 3.500t 5052 H112 aluminum plate | 3.500 | 90 | 1500*3000 |

| ASTM B209 3.750t 5052 H112 aluminum plate | 3.750 | 95 | 1500*3000 |

| ASTM B209 4.000t 5052 H112 aluminum plate | 4.000 | 100 | 1500*3000 |

Mechanical properties of 5052 H112 aluminum plate

| Specified thickness mm | Tensile strength Rm MPa | Yield strength Rp0,2 MPa | Elongation min.% | Hardness HBWa | ||

|---|---|---|---|---|---|---|

| over | up to | A50 mm | A | |||

| 6.0 | 12.5 | 190 | 80 | 7 | 55 | |

| 12.5 | 40.0 | 170 | 70 | 10 | 47 | |

| 40.0 | 80.0 | 170 | 70 | 14 | 47 | |

Chemical composition of 5052 H112 aluminum plate

| Element | Composition % |

|---|---|

| Si | 0.25 |

| Fe | 0.4 |

| Cu | 0.1 |

| Mn | 0.1 |

| Mg | 2.2-2.8 |

| Cr | 0.15-0.35 |

| Zn | 0.1 |

| Each | 0.05 |

| Total | 0.15 |

| Min | Remainder |

Thermal properties of 5052 H112 aluminum plate

| Thermal properties | Metric | English |

|---|---|---|

| Latent heat of fusion | 400 J/g | |

| Maximum temperature: mechanical | 190 °C | 370 °F |

| Melting completion (liquidus) | 650 °C | 1200 °F |

| Melting onset (solidus) | 610 °C | 1120 °F |

| Specific Heat Capacity | 900 J/kg-K | 0.22 BTU/lb-°F |

| Thermal conductivity | 140 W/m-K | 80 BTU/h-ft-°F |

| Thermal expansion | 24 µm/m-K |

Application of 5052 H112 aluminum plate

5052 H112 anodized aluminum plate and color coated aluminum plate

The addition of magnesium element improves the processability and oxidation resistance of 5052 aluminum plate, making the surface of 5052 aluminum plate smoother, with stronger adhesion, easy anodizing and coating processing, and effectively preventing the formation of oxide layer.

- 5052 H112 color coated aluminum plate is widely used on the outer skin of ships, refrigerated car carriages, box trucks, RVs, etc.

- 5052 H112 anodized aluminum plate is widely used in the fields of digital electronic products, cosmetic can covers, decorative signs, and high-end curtain walls.

5052 H112 treat checkered aluminum plate

5052 patterned treat checkered plate combines anti slip, aesthetic and corrosion resistance, and is mainly used in the following fields:

- Ship deck and dock slab;

- Toolbox and cabinet finishes;

- Recreational vehicles, freight vehicles, and public trailer pedals; Anti slip flooring for fire trucks;

- Car rear bumper protection device;

- Stair treads and floors.

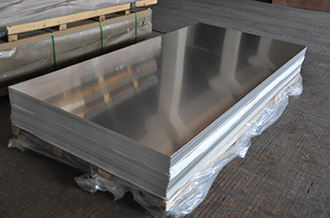

5052 H112 aluminum sheet

- Car body shell and decorative parts;

- Electronic product shell, panel, backplane, computer stand;

- Furniture, aluminum cabinets, door panels, door handles, decorative strips, blinds and other home furnishings;

- Billboards, signs, and advertising letter casings.

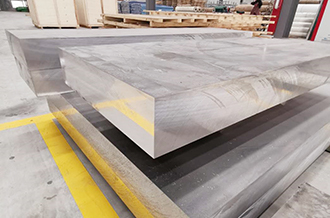

5052 H112 aluminum plate

- Structural components of industrial equipment, such as tanks, storage tanks, equipment casings, silos, etc.;

- Flange material;

- GIS (Gas Insulated Switchgear) casing;

- Underwear molds/shoe molds.

Related products