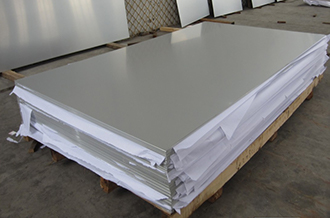

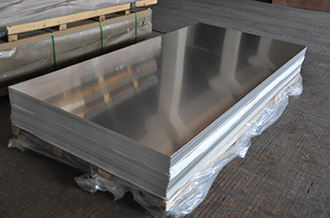

5052 H32 Aluminium Sheet Plate

Thickness:0.2-40mm

Tensile strength:210-260 MPa

Certification: ISO9001, SGS, ROSH

Other features: high strength, high plasticity and corrosion resistance, good corrosion resistance, good weldability.

5052 H32 is an annealing process that accounts for a large proportion of the entire use. This annealing temperature is generally direct annealing at 420 degrees - 475 degrees, which has the advantages of high temperature resistance, corrosion resistance, and oxidation resistance.

Common stocks and sizes of 5052 H32 aluminum plates

| Description | Thickness/in | Metric Thickness/mm | Width*Length/mm |

|---|---|---|---|

| 0.04t 5052 H32 Aluminum Sheet | 0.04 | 1 | 1250x2500 |

| 0.04t 5052 H32 Aluminum Sheet | 0.04 | 1 | 1500x3000 |

| 0.1t 5052 H32 Aluminum Sheet | 0.1 | 2.5 | 1250x2500 |

| 0.1t 5052 H32 Aluminum Sheet | 0.1 | 2.5 | 1500x3000 |

| 0.12t 5052 H32 Aluminum Sheet | 0.12 | 3 | 1500x3000 |

| 0.16t 5052 H32 Aluminum Sheet | 0.16 | 4 | 1500x3000 |

| 0.2t 5052 H32 Aluminum Sheet | 0.2 | 5 | 1000x2000 |

| 0.24t 5052 H32 Aluminum Sheet | 0.24 | 6 | 1500x3000 |

Mechanical properties of 5052 aluminum plate

| Specified thickness mm | Tensile strength Rm/MPa | Yield strength Rp0,2/MPa | Elongation min.% | Bend radiusa | Hardness HBWa | |||

|---|---|---|---|---|---|---|---|---|

| over | up to | min. | max. | min. | A50 mm | 180° | 90° | |

| 0,2 | 0,5 | 210 | 260 | 130 | 5 | 1,5 t | 0,5 t | 61 |

| 0,5 | 1,5 | 210 | 260 | 130 | 6 | 1,5 t< | t | 61 |

| 1,5 | 3,0 | 210 | 260 | 130 | 7 | 1,5 t | 1,5 t | 61 |

| 3,0 | 6,0 | 210 | 260 | 130 | 10 | - | 1,5 t | 61 |

| 6,0 | 12,5 | 210 | 260 | 130 | 12 | - | 2,5 t | 61 |

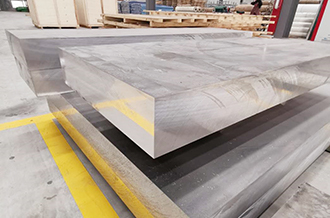

| 12,5 | 40,0 | 210 | 260 | 130 | - | - | - | 61 |

5052 aluminum plate chemical composition

| Element | chemical composition % |

|---|---|

| Si | 0.25 |

| Fe | 0.4 |

| Cu | 0.1 |

| Mn | 0.1 |

| Mg | 2.2-2.8 |

| Cr | 0.15-0.35 |

| Zn | 0.1 |

| Al | Remainder |

Processing technology: hot rolling

H32 temper product production process: smelting → casting → sawing → milling → heating → hot rolling → cold rolling → cleaning → intermediate annealing → cold rolling → stabilization annealing → finishing → inspection → packaging

Application of 5052 aluminium plate sheet

- Car engine outer panels, bus trunk panels, anti-skid decorative panels for buses, aluminum panels for automobile fuel tanks;

- 5052 aluminum plate is used in automobiles, meets the requirements of automobile lightweight, and has high strength, corrosion resistance and high temperature resistance;

- Aluminum plate for small yachts;

- 5052 aluminum plates are used on ship plates to enhance the strength and stability of the overall structure, are corrosion-resistant and have good weldability.

- Electronic instrument panels, distribution box electrical enclosures, chassis cabinets;

- 5052 aluminum plate is used on the outer panel of electronic products. It can resist oxidation, high temperature and has good stamping effect.

5052 aluminium plate sheet performance advantages

- For applications requiring high plasticity and good weldability

- The plasticity is still good during semi-cold work hardening

- Low plasticity during cold work hardening

- Good corrosion and good weldability.

Related products