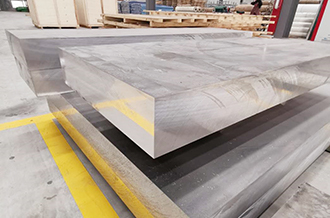

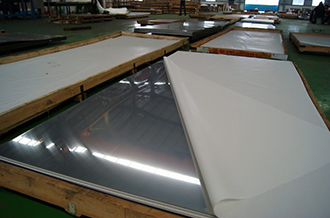

5083 O H111 Aluminum plate

5083 O/H111 aluminum plate, containing magnesium, manganese traces, and chromium, denotes fully annealed or minimally processed-hardened aluminum sheets. Compared to 5083 H116/H321 aluminum plates, O H111 variants are softer but offer higher ductility and workability while maintaining exceptional resistance against seawater and industrial chemical corrosion.

Renowned for its capability to withstand low temperatures without brittleness or property loss, 5083 aluminum plates are highly favored in cold temperature applications. They find extensive use in offshore platforms, ocean-going vessel construction, LNG carriers, pressure vessels, railway vehicles, and other similar fields.

Stock size list for 5083 O H111 aluminum plate

| Description | Thickness/in | Thickness/mm | Size/mm |

|---|---|---|---|

| 0.04" 5083 O/H111 Aluminum Sheet | 1 | 0.04 | 1250x2500 |

| 0.04" 5083 O/H111 Aluminum Sheet | 1 | 0.04 | 1500x3000 |

| 0.06" 5083 O/H111 Aluminum Sheet | 1.5 | 0.06 | 1250x2500 |

| 0.06" 5083 O/H111 Aluminum Sheet | 1.5 | 0.06 | 1500x3000 |

| 0.08" 5083 O/H111 Aluminum Sheet | 2 | 0.08 | 1250x2500 |

| 0.08" 5083 O/H111 Aluminum Sheet | 2 | 0.08 | 1500x3000 |

| 0.1" 5083 O/H111 Aluminum Sheet | 2.5 | 0.1 | 1500x3000 |

| 1/8" 5083 O/H111 Aluminum Sheet | 2.95 | 1/8 | 1500x3000 |

| 1/8" 5083 O/H111 Aluminum Sheet | 3 | 1/8 | 1250x2500 |

| 1/8" 5083 O/H111 Aluminum Sheet | 3 | 1/8 | 1500x3000 |

| 0.16" 5083 O/H111 Aluminum Sheet | 4 | 0.16 | 1250x2500 |

| 0.16" 5083 O/H111 Aluminum Sheet | 4 | 0.16 | 1500x3000 |

| 0.2" 5083 O/H111 Aluminum Sheet | 5 | 0.2 | 1250x2500 |

| 0.2" 5083 O/H111 Aluminum Sheet | 5 | 0.2 | 1500x3000 |

| 1/4" 5083 O/H111 Aluminum Sheet | 6 | 1/4 | 1250x2500 |

| 1/4" 5083 O/H111 Aluminum Sheet | 6 | 1/4 | 1500x3000 |

| 0.31" 5083 O/H111 Aluminum Plate | 8 | 0.31 | 2000x4000 |

| 0.39" 5083 O/H111 Aluminum Plate | 10 | 0.39 | 2000x4000 |

| 0.47" 5083 O/H111 Aluminum Plate | 12 | 0.47 | 2000x4000 |

| 5/8" 5083 O/H111 Aluminum Plate | 16 | 5/8 | 2000x4000 |

| 0.71" 5083 O/H111 Aluminum Plate | 18 | 0.71 | 2000x4000 |

| 0.87" 5083 O/H111 Aluminum Plate | 22 | 0.87 | 2000x4000 |

| 0.98" 5083 O/H111 Aluminum Plate | 25 | 0.98 | 2000x4000 |

| 1.1" 5083 O/H111 Aluminum Plate | 28 | 1.1 | 2000x4000 |

| 1.38" 5083 O/H111 Aluminum Plate | 35 | 1.38 | 2000x4000 |

| 1.77" 5083 O/H111 Aluminum Plate | 45 | 1.77 | 2000x4000 |

| 1.97" 5083 O/H111 Aluminum Plate | 50 | 1.97 | 2000x4000 |

| 2.36" 5083 O/H111 Aluminum Plate | 60 | 2.36 | 2000x4000 |

| 2.56" 5083 O/H111 Aluminum Plate | 65 | 2.56 | 2000x4000 |

| 2.76" 5083 O/H111 Aluminum Plate | 70 | 2.76 | 2000x4000 |

| 3.15" 5083 O/H111 Aluminum Plate | 80 | 3.15 | 2000x4000 |

| 3.54" 5083 O/H111 Aluminum Plate | 90 | 3.54 | 2000x4000 |

Mechanical properties of 5083 O/H111 aluminum plate

| Temper | Specified thickness mm | Tensile strength Rm/MPa | Yield strength Rp0.2/MPa | Elongation min.% | Bend radiusa | Hardness HBWa | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| over | up to | min. | max. | min. | A50 mm | A | 180° | 90° | ||

| O | 0.2 | 0.5 | 275 | 350 | 125 | 11 | - | 1.0 t | 0.5 t | 75 |

| O | 0.5 | 1.5 | 275 | 350 | 125 | 12 | - | 1.0 t | 1.0 t | 75 |

| O | 1.5 | 3.0 | 275 | 350 | 125 | 13 | - | 1.5 t | 1.0 t | 75 |

| O | 3.0 | 6.3 | 275 | 350 | 125 | 15 | - | - | 1.5 t | 75 |

| O | 6.3 | 12.5 | 270 | 345 | 115 | 16 | - | - | 2.5 t | 75 |

| O | 12.5 | 50.0 | 270 | 345 | 115 | - | 15 | - | - | 75 |

| O | 50.0 | 80.0 | 270 | 345 | 115 | - | 14 | - | - | 73 |

| O | 80.0 | 120.0 | 260 | - | 110 | - | 12 | - | - | 70 |

| O | 120.0 | 200.0 | 255 | - | 105 | - | 12 | - | - | 69 |

| O | 200.0 | 250.0 | 250 | - | 95 | 10 | - | - | 69 | |

| O | 250.0 | 300.0 | 245 | - | 90 | - | 9 | - | - | 69 |

| H111 | 0.2 | 0.5 | 275 | 350 | 125 | 11 | - | 1.0 t | 0.5 t | 75 |

| H111 | 0.5 | 1.5 | 275 | 350 | 125 | 12 | - | 1.0 t | 1.0 t | 75 |

| H111 | 1.5 | 3.0 | 275 | 350 | 125 | 13 | - | 1.5 t | 1.0 t | 75 |

| H111 | 3.0 | 6.3 | 275 | 350 | 125 | 15 | - | - | 1.5 t | 75 |

| H111 | 6.3 | 12.5 | 270 | 345 | 115 | 16 | - | - | 2.5 t | 75 |

| H111 | 12.5 | 50.0 | 270 | 345 | 115 | - | 15 | - | - | 75 |

| H111 | 50.0 | 80.0 | 270 | 345 | 115 | - | 14 | - | - | 73 |

| H111 | 80.0 | 120.0 | 260 | - | 110 | - | 12 | - | - | 70 |

| H111 | 120.0 | 200.0 | 255 | - | 105 | - | 12 | - | - | 69 |

| H111 | 200.0 | 250.0 | 250 | - | 95 | - | 10 | - | - | 69 |

| H111 | 250.0 | 300.0 | 245 | - | 90 | - | 9 | - | - | 69 |

Chemical composition of 5083 aluminum plate

| Element | Composition % |

|---|---|

| Si | ≤0.40 |

| Fe | ≤0.40 |

| Cu | ≤0.10 |

| Mn | 0.4-1.0 |

| Mg | 4.0-4.9 |

| Cr | 0.05-0.25 |

| Zn | ≤0.25 |

| Ti | ≤0.15 |

| Each | ≤0.05 |

| Total | ≤0.15 |

| Al | Re |

Thermal properties of 5083 O/H111 aluminum plate

| Physical Properties | Metric | English | Comments |

|---|---|---|---|

| CTE, linear 68°F | 23.8 µm/m-°C | 13.2 µin/in-°F | AA; Typical; Average over 68-212°F range |

| CTE, linear 250°C | 26 µm/m-°C | 14.4 µin/in-°F | Average over the range 20-300ºC |

| Specific Heat Capacity | 0.9 J/g-°C | 0.215 BTU/lb-°F | |

| Thermal Conductivity | 117 W/m-K | 810 BTU-in/hr-ft²-°F | AA; Typical at 77°F |

| Melting Point | 591-638 °C | 1095 - 1200 °F | AA; Typical range based on typical composition for wrought products 1/4 inch thickness or greater |

| Solidus | 591 °C | 1095 °F | AA; Typical |

| Liquidus | 638 °C | 1180 °F | AA; Typical |

Applications of 5083 O aluminum plate

LNG ships

5083-O aluminum plates are commonly used in the construction of Liquefied Natural Gas (LNG) ships due to their stable performance at extremely low temperatures, exhibiting excellent properties even at temperatures as low as -195°C.

Pressure vessels

Because of its good performance under low-temperature conditions, 5083-O aluminum plates are often utilized in manufacturing low-temperature storage tanks and pressure vessels.

Shipbuilding

5083-O aluminum plates for marine applications possess high ductility and workability, finding widespread use in ship construction, particularly in areas like hulls, bulkheads, and ship bottoms.

Tanker trucks

5083-O aluminum plates used in tanker trucks showcase good malleability and processing properties, along with excellent welding performance, enabling reliable double-side welding with the tank body. This ensures the tanker's sealing and structural strength, commonly applied in the construction of tanker heads and wave baffles.

Applications of 5083 H111 aluminum plate

Shipbuilding

5083-H111 aluminum plates are widely used in shipbuilding, typically employed in constructing the hull, deck, sides, and other components of ships.

Pressure vessels and welded structures

The forming process of 5083-H111 aluminum plates provides them with a certain degree of work-hardening, often utilized in manufacturing pressure vessels and high-strength welded structures.

Vehicle bodies and automotive components

In the transportation sector, 5083-H111 aluminum plates are highly regarded for their lightweight, corrosion resistance, and weldability. They are extensively applied in automotive bodies, aircraft fuel tanks, and other components.

Other products of 5083 aluminum sheet

- 5083-O aluminum sheet is achieved through full annealing, offering higher ductility and workability but slightly lower strength compared to other processing temper.

- 5083-H111 aluminum sheet experiences some work hardening during shaping but relatively less compared to 5083-O, commonly interchangeable.

- 5083-H112 aluminum sheet exhibits lower strength and mechanical properties than the 5083-H32 temper.

- 5083-H116/H321 aluminum sheet demonstrates improved corrosion resistance, particularly suitable for underwater marine environments.

- 5083-H32 aluminum sheet, after work hardening and subsequent low-temperature treatment, possesses relatively higher tensile strength and corrosion resistance.

Overall, 5083 aluminum sheet is an excellent anti-corrosive material, well-suited for marine climates, and widely used in damp and marine environments. It finds applications in pressure vessels, dump truck bodies, railcars, shipbuilding, vehicle bodies, among other fields.

Related products

5052 O H111 aluminum plate

5086 O H111 aluminum plate

5754 O H111 aluminum plate

5454 H32 aluminum plate

6061 T6 aluminum plate

6082 T6 aluminum plate