5086 H112 Aluminum Sheet

5086 aluminum plate belongs to the 5000 series aluminum-magnesium alloy, typically containing no more than 7% magnesium. It possesses good corrosion resistance, moderate strength, excellent weldability, and is highly favored in marine applications.

Commonly used in various fields such as transportation, pressure vessels, low-temperature equipment, tower structures, drilling rigs, oil/natural gas pipelines, military armored plates, among others. In shipbuilding, 5086 aluminum plate is frequently used, especially for bulkheads, fuel tanks, and ship compartments. It is also extensively employed in pressure vessels, low-temperature equipment, tower structures, drilling rigs, oil/natural gas pipelines, and military armored plates.

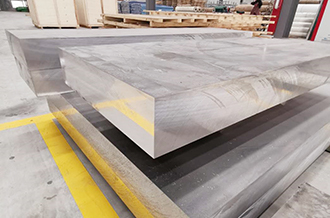

Hot selling sizes of 5086 H112 aluminum sheet

| Description | Thickness/in | Thickness/mm | Size/mm |

|---|---|---|---|

| 0.31" 5086 H112 Aluminum Plate | 8 | 0.31 | 1500x3000 |

| 0.47" 5086 H112 Aluminum Plate | 12 | 0.47 | 1500x3000 |

| 0.98" 5086 H112 Aluminum Plate | 25 | 0.98 | 2000x4000 |

| 1.18" 5086 H112 Aluminum Plate | 30 | 1.18 | 2000x4000 |

| 1.18" 5086 H112 Aluminum Plate | 30 | 1.18 | 2000x4000 |

| 2.36" 5086 H112 Aluminum Plate | 60 | 2.36 | 2000x4000 |

| 2.95" 5086 H112 Aluminum Plate | 75 | 2.95 | 2000x4000 |

| 2.95" 5086 H112 Aluminum Plate | 75 | 2.95 | 2000x4000 |

| 3.15" 5086 H112 Aluminum Plate | 80 | 3.15 | 2000x4000 |

| 3.54" 5086 H112 Aluminum Plate | 90 | 3.54 | 2000x4000 |

| 4.33" 5086 H112 Aluminum Plate | 110 | 4.33 | 2000x4000 |

| 4.33" 5086 H112 Aluminum Plate | 110 | 4.33 | 2000x4000 |

| 5.12" 5086 H112 Aluminum Plate | 130 | 5.12 | 2000x4000 |

| 5.12" 5086 H112 Aluminum Plate | 130 | 5.12 | 2000x4000 |

| 5.51" 5086 H112 Aluminum Plate | 140 | 5.51 | 2000x4000 |

| 5.51" 5086 H112 Aluminum Plate | 140 | 5.51 | 2000x4000 |

| 6.3" 5086 H112 Aluminum Plate | 160 | 6.30 | 2000x4000 |

Mechanical properties of 5086 H112 aluminum sheet

| Temper | Specified thickness mm | Tensile strength Rm/MPa | Yield strength Rp0,2/MPa | Elongation min.% | Hardness HBWa | ||

|---|---|---|---|---|---|---|---|

| over | up to | min. | min. | A50 mm | A | ||

| H112 | ³ 6,0 | 12,5 | 250 | 105 | 8 | - | 69 |

| H112 | 12,5 | 40,0 | 240 | 105 | - | 9 | 65 |

| H112 | 40,0 | 80,0 | 240 | 100 | - | 12 | 65 |

Chemical composition of 5086 aluminum sheet

| Element | Composition % |

|---|---|

| Si | ≤0.40 |

| Fe | ≤0.50 |

| Cu | ≤0.10 |

| Mn | 0.2-0.7 |

| Mg | 3.5-4.5 |

| Cr | 0.05-0.25 |

| Zn | ≤0.25 |

| Ti | ≤0.15 |

| Each | ≤0.05 |

| Total | ≤0.15 |

| Al | Re |

Thermal properties of 5086 H112 aluminum sheet

| Physical Properties | Metric | English | Comments |

|---|---|---|---|

| CTE, linear 68°F | 23.8 µm/m-°C | 13.2 µin/in-°F | AA; Typical; Average over 68-212°F range |

| CTE, linear 250°C | 25.8 µm/m-°C | 14.3 µin/in-°F | Average over the range 20-300ºC |

| Specific Heat Capacity | 0.9 J/g-°C | 0.215 BTU/lb-°F | |

| Thermal Conductivity | 125 W/m-K | 870 BTU-in/hr-ft²-°F | AA; Typical at 77°F |

| Melting Point | 585-641 °C | 1085 - 1185 °F | AA; Typical range based on typical composition for wrought products 1/4 inch thickness or greater |

| Solidus | 585 °C | 1085 °F | AA; Typical |

| Liquidus | 641 °C | 1185 °F | AA; Typical |

Applications of 5083 H112 aluminum sheet

Marine vessels

5086 aluminum alloy is widely used in marine applications due to its resistance to saltwater corrosion, excellent welding properties, and outstanding corrosion resistance in seawater. It is utilized in the manufacturing of ship sides, bottoms, outer walls, and decks.

Pressure vessels/low-temperature equipment

5086 H112 aluminum plate exhibits properties resistant to degradation or damage in high-temperature and high-pressure environments, making it suitable for pressure vessels and refrigeration systems that have strict fire resistance requirements.

Transportation equipment

It finds broad applications in the manufacturing of transport vehicles, weldable components for automobiles, and transportation equipment where high corrosion resistance, good weldability, and moderate strength are required.

Other products of 5086 aluminum plate

- 5086 H111 Aluminum Plate: This grade offers high strength with an elastic modulus ranging from 70 to 80 GPa and a Poisson's ratio of 0.33. These plates have a thermal expansion rate of 23.9 (10-6/°C) and a thermal conductivity of 127 (W/mK).

- 5086 H112 Aluminum Plate: The H112 temper is essentially a variant of the F temper, allowing limited hardening or heat treatment. It resists degradation or damage when exposed to high temperatures and pressures within systems.

- 5086 H116 Aluminum Plate: This strain-hardened plate exhibits excellent mechanical properties.

- 5086 H32 Aluminum Plate: It offers the best metalworking capabilities and ensures tight radii during bending.

These different grades such as H111, H112, H116, H32 have varying mechanical properties and application characteristics. 5086 aluminum alloy is highly favored in marine applications due to its exceptional corrosion resistance and weldability.

Related products

5052 H112 aluminum plate

5083 H112 aluminum plate

5754 H112 aluminum plate

5454 H32 aluminum plate

6061 T6 aluminum plate

6082 T6 aluminum plate