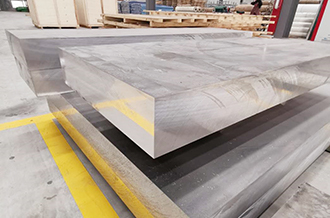

7075 T73 T7351 Aluminum Sheet Plate

7075 is an aluminum-zinc alloy plate. Aluminum plates in the 7075 T73 T7351 temper exhibit high fracture toughness and excellent resistance to stress corrosion cracking. They achieve extremely high strength levels after precipitation hardening and are used in the manufacturing of high-stress components, aircraft structures, high-end automobiles, and the defense industry.

Hot selling sizes of 7075 T73 T7351 aluminum sheet plate

| Description | Thickness/mm | Thickness/in | Width×Length/in |

|---|---|---|---|

| 0.032" 7075 T73 Aluminum Sheet | 0.81 | 0.032 | 48.5×144.5 |

| 0.04" 7075 T73 Aluminum Sheet | 1.02 | 0.04 | 48.5×144.5 |

| 0.04" 7075 T73 Aluminum Sheet | 1.02 | 0.04 | 60.5×144.5 |

| 0.05" 7075 T73 Aluminum Sheet | 1.27 | 0.05 | 48.5×144.5 |

| 0.05" 7075 T73 Aluminum Sheet | 1.27 | 0.05 | 48.5×144.5 |

| 0.063" 7075 T73 Aluminum Sheet | 1.6 | 0.063 | 48.5×144.5 |

| 0.08" 7075 T73 Aluminum Sheet | 2.03 | 0.08 | 48.5×144.5 |

| 0.08" 7075 T73 Aluminum Sheet | 2.03 | 0.08 | 60.5×144.5 |

| 0.09" 7075 T73 Aluminum Sheet | 2.29 | 0.09 | 48.5×144.5 |

| 0.1" 7075 T73 Aluminum Sheet | 2.54 | 0.1 | 48.5×144.5 |

| 0.1" 7075 T73 Aluminum Sheet | 2.54 | 0.1 | 60.5×144.5 |

| 1/8" 7075 T73 Aluminum Sheet | 3.18 | 1/8 | 48.5×144.5 |

| 1/8" 7075 T73 Aluminum Sheet | 3.18 | 1/8 | 60.5×144.5 |

| 0.16" 7075 T73 Aluminum Sheet | 4.06 | 0.16 | 48.5×144.5 |

| 0.16" 7075 T73 Aluminum Sheet | 4.06 | 0.16 | 60.5×144.5 |

| 0.19" 7075 T73 Aluminum Sheet | 4.83 | 0.19 | 48.5×144.5 |

| 1/4" 7075 T73 Aluminum Sheet | 6.35 | 1/4 | 48.5×144.5 |

| 1/4" 7075 T7351 Aluminum Sheet | 6.35 | 1/4 | 60.5×144.5 |

| 1/4" 7075 T7351 Aluminum Sheet | 6.35 | 1/4 | 48.5×144.5 |

| 3/8" 7075 T7351 Aluminum Plate | 9.53 | 3/8 | 48.5×144.5 |

| 3/8" 7075 T7351 Aluminum Plate | 9.53 | 3/8 | 60.5×144.5 |

| 1/2" 7075 T7351 Aluminum Plate | 12.7 | 1/2 | 48.5×144.5 |

| 5/8" 7075 T7351 Aluminum Plate | 15.88 | 5/8 | 48.5×144.5 |

| 0.75" 7075 T7351 Aluminum Plate | 19.05 | 0.75 | 48.5×144.5 |

| 1" 7075 T7351 Aluminum Plate | 25.4 | 1 | 48.5×144.5 |

| 1.25" 7075 T7351 Aluminum Plate | 31.75 | 1.25 | 48.5×144.5 |

| 1.5" 7075 T7351 Aluminum Plate | 38.1 | 1.5 | 48.5×144.5 |

| 1.75" 7075 T7351 Aluminum Plate | 44.45 | 1.75 | 48.5×144.5 |

| 2" 7075 T7351 Aluminum Plate | 50.8 | 2 | 48.5×144.5 |

| 2.25" 7075 T7351 Aluminum Plate | 57.15 | 2.25 | 48.5×144.5 |

| 2.5" 7075 T7351 Aluminum Plate | 63.5 | 2.5 | 48.5×144.5 |

| 2.75" 7075 T7351 Aluminum Plate | 69.85 | 2.75 | 48.5×144.5 |

| 3" 7075 T7351 Aluminum Plate | 76.2 | 3 | 48.5×144.5 |

| 3.125" 7075 T7351 Aluminum Plate | 79.38 | 3.125 | 48.5×144.5 |

| 3.5" 7075 T7351 Aluminum Plate | 88.9 | 3.5 | 48.5×144.5 |

| 4" 7075 T7351 Aluminum Plate | 101.6 | 4 | 48.5×144.5 |

| 4.5" 7075 T7351 Aluminum Plate | 114.3 | 4.5 | 48.5×144.5 |

| 5" 7075 T7351 Aluminum Plate | 127 | 5 | 48.5×144.5 |

| 5.5" 7075 T7351 Aluminum Plate | 139.7 | 5.5 | 48.5×144.5 |

| 6" 7075 T7351 Aluminum Plate | 152.4 | 6 | 48.5×144.5 |

Mechanical properties of 7075 T73 T7351 aluminum sheet plate

| Temper | Specified thickness mm | Tensile strength Rm/MPa | Yield strength Rp0.2/MPa | Elongation min.% | Hardness HBWa | ||

|---|---|---|---|---|---|---|---|

| over | up to | min. | min. | A50 mm | A | ||

| T73 | ≥1.5 | 3.0 | 460 | 385 | 7 | - | 137 |

| T73 | 3.0 | 6.0 | 460 | 385 | 8 | - | 137 |

| T73 | 6.0 | 12.5 | 475 | 390 | 7 | - | 140 |

| T73 | 12.5 | 25.0 | 475 | 390 | - | 6 | 140 |

| T73 | 25.0 | 50.0 | 475 | 390 | - | 5 | 140 |

| T73 | 50.0 | 60.0 | 455 | 360 | - | 5 | 133 |

| T73 | 60.0 | 80.0 | 440 | 340 | - | 5 | 129 |

| T73 | 80.0 | 100.0 | 430 | 340 | - | 5 | 126 |

| T7351 | ≥1.5 | 3.0 | 460 | 385 | 7 | - | 137 |

| T7351 | 3.0 | 6.0 | 460 | 385 | 8 | - | 137 |

| T7351 | 6.0 | 12.5 | 475 | 390 | 7 | - | 140 |

| T7351 | 12.5 | 25.0 | 475 | 390 | - | 6 | 140 |

| T7351 | 25.0 | 50.0 | 475 | 390 | - | 5 | 140 |

| T7351 | 50.0 | 60.0 | 455 | 360 | - | 5 | 133 |

| T7351 | 60.0 | 80.0 | 440 | 340 | - | 5 | 129 |

| T7351 | 80.0 | 100.0 | 430 | 340 | - | 5 | 126 |

Chemical composition of 7075 T73 T7351 aluminum sheet plate

| Element | Composition % |

|---|---|

| Si | 0.40-1.00 |

| Fe | 0.5 |

| Cu | 1.2-2.0 |

| Mn | 0.3 |

| Mg | 2.1-2.9 |

| Cr | 0.18-0.28 |

| Zn | 5.1-6.1 |

| Ti | 0.25 |

| Each | 0.05 |

| Total | 0.15 |

| Al | Re |

Thermal properties of 7075 T73 T7351 aluminum sheet plate

| Physical Properties | Metric | English | Comments |

|---|---|---|---|

| CTE, linear 68°F | 23.6 µm/m-°C | 13.1 µin/in-°F | AA; Typical; Average over 68-212°F range |

| CTE, linear 250°C | 25.2 µm/m-°C | 14 µin/in-°F | Average over the range 20-300°C |

| Specific Heat Capacity | 0.96J/g-°C | 0.229 BTU/lb-°F | |

| Thermal Conductivity | 155 W/m-K | 1080 BTU-in/hr-ft²-°F | |

| Melting Point | 477-635 °C | 890-1175 °F | AA; Typical range based on typical composition for wrought products 1/4 inch thickness or greater. Homogenization may raise eutectic melting temperature 20-40°F but usually does not eliminate eutectic melting. |

| Solidus | 477°C | 890 °F | AA; Typical |

| Liquidus | 635°C | 1175 °F | AA; Typical |

Applications of 7075 T73 T7351 aluminum sheet plate

Aircraft fuselage structures

7075 aluminum plates are extensively used in the aerospace industry, especially in aircraft fuselage structures and frames. This is due to its high strength, lightweight properties, corrosion resistance, and excellent strength-to-weight ratio, making it an ideal choice for manufacturing aircraft components.

Bearings and gears

7075 T73/T7351 aluminum plates exhibit exceptional fatigue resistance and stress corrosion cracking resistance, making them highly suitable for high-stress environments. Therefore, they are commonly used in manufacturing high-performance bearings and gears.

Missile components

7075 T73/T7351 aluminum plates play a critical role in missile manufacturing due to their lightweight nature and outstanding stress corrosion cracking resistance, making them suitable for use in various extreme conditions.

Defense and military applications

Compared to 7075 T6 T651 aluminum plates, 7075 T73/T7351 aluminum plates might sacrifice some strength but significantly enhance durability. They find widespread use in structural components within the defense and military industries.

Related products