7475 T7351 T651 Aluminum Plate

7475 aluminum alloy plate is mainly composed of aluminum, zinc, copper and small amounts of other alloying elements such as magnesium, manganese and chromium. 7475 T7351 has been artificially aged (T7 temper) and stabilized (T351 temper) to have high strength and excellent stress corrosion resistance.

7475 T651 high-strength aluminum alloy plate. After aging treatment (T6 temper) and stabilization treatment (T51 temper), the strength of the aluminum plate is improved and good resistance to stress corrosion cracking is maintained.

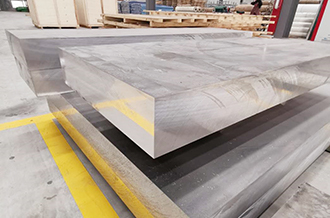

7475 T7351 T651 aluminum plate sizes and stock

| Thickness /Alloy /Temper | Width(mm) | Length(mm) |

|---|---|---|

| 12.7mm 7475 T7351 /T651 | 1250 | 2500 |

| 15.88mm 7475 T7351 /T651 | 1250 | 2500 |

| 19.05mm 7475 T7351 /T651 | 1250 | 2500 |

| 22.86mm 7475 T7351 /T651 | 1500 | 3000 |

| 25.4mm 7475 T7351 /T651 | 1500 | 3000 |

| 31.75mm 7475 T7351 /T651 | 1500 | 3000 |

| 38.1mm 7475 T7351 /T651 | 1500 | 3000 |

| 40.8mm 7475 T7351 /T651 | 1500 | 3000 |

| 44.45mm 7475 T7351 /T651 | 1500 | 3000 |

| 50.8mm 7475 T7351 /T651 | 1500 | 3000 |

| 55mm 7475 T7351 /T651 | 1500 | 3000 |

| 57.15mm 7475 T7351 /T651 | 1500 | 3000 |

| 60.96mm 7475 T7351 /T651 | 1500 | 3000 |

| 63.5mm 7475 T7351 /T651 | 1500 | 3000 |

| 76.2mm 7475 T7351 /T651 | 1500 | 3000 |

| 80mm 7475 T7351 /T651 | 1500 | 3000 |

| 85mm 7475 T7351 /T651 | 1500 | 3000 |

| 95mm 7475 T7351 /T651 | 1500 | 3000 |

| 101.6mm 7475 T7351 /T651 | 1500 | 3000 |

| 110mm 7475 T7351 /T651 | 1500 | 3000 |

| 114.3mm 7475 T7351 /T651 | 1500 | 3000 |

| 127mm 7475 T7351 /T651 | 1500 | 3000 |

| 152mm 7475 T7351 /T651 | 1500 | 3000 |

| Can be customized according to customer requirement | ||

7475 aluminum plate chemical composition

| Chemical compositions of the 7475-T7351 aluminum alloy (mass fraction/%) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Zn | Mg | Cu | Mn | Cr | Ti | Fe | Si | Al |

| 5.89 | 2.48 | 1.59 | 0.0017 | 0.22 | 0.017 | 0.056 | < 0.03 | Bal |

7475 T7351 T651 aluminum plate mechanical properties

| Temper | T7351 | T651 |

|---|---|---|

| Elastic (Young's, Tensile) Modulus | 70 GPa10 x 106 psi | 70 GPa10 x 106 psi |

| Elongation at Break | 12 % | 12 % |

| Fatigue Strength | 190 MPa28 x 103 psi | 210 MPa31 x 103 psi |

| Poisson's Ratio | 0.32 | 0.32 |

| Shear Modulus | 26 GPa3.8 x 106 psi | 26 GPa3.8 x 106 psi |

| Shear Strength | 320 MPa46 x 103 psi | 350 MPa51 x 103 psi |

| Tensile Strength: Ultimate (UTS) | 530 MPa76 x 103 psi | 590 MPa85 x 103 psi |

| Tensile Strength: Yield (Proof) | 440 MPa64 x 103 psi | 520 MPa75 x 103 psi |

7475 T7351 T651 aluminum plate thermal properties

| Temper | T7351 | T651 |

|---|---|---|

| Latent Heat of Fusion | 380 J/g | 380 J/g |

| Maximum Temperature: Mechanical | 180 °C350 °F | 180 °C350 °F |

| Melting Completion (Liquidus) | 640 °C1180 °F | 640 °C1180 °F |

| Melting Onset (Solidus) | 480 °C890 °F | 480 °C890 °F |

| Specific Heat Capacity | 870 J/kg-K0.21 BTU/lb-°F | 870 J/kg-K0.21 BTU/lb-°F |

| Thermal Conductivity | 160 W/m-K94 BTU/h-ft-°F | 140 W/m-K80 BTU/h-ft-°F |

| Thermal Expansion | 23 µm/m-K | 23 µm/m-K |

7075 T7351 T651 aluminum plate electrical properties

| Alloy /Temper | Electrical Conductivity: Equal Volume | Electrical Conductivity: Equal Weight (Specific) |

|---|---|---|

| 7475 /T7351 | 42 % IACS | 120 % IACS |

| 7475/T651 | 34 % IACS | 100 % IACS |

7475 T7351 T651 aluminium plate otherwise unclassified properties

| Alloy /Temper | Density | Embodied Carbon | Embodied Energy | Embodied Water |

|---|---|---|---|---|

| 7475 /T7351 | 3.0 g/cm3190 lb/ft3 | 8.2 kg CO2/kg material | 150 MJ/kg63 x 103 BTU/lb | 1130 L/kg130 gal/lb |

| 7475/T651 | 3.0 g/cm3190 lb/ft3 | 8.2 kg CO2/kg material | 150 MJ/kg63 x 103 BTU/lb | 1130 L/kg130 gal/lb |

7475 T7351 T651 aluminium plate application

Aerospace industry

7475 T7351 T651 aluminum plate is commonly used to manufacture aircraft structures and components, such as wings, rudder surfaces, fuselages and landing gear. Its high strength, lightweight properties and corrosion resistance help improve the service life and fuel efficiency of the aircraft.

7475 T651 aluminum plate is also commonly used to manufacture parts for spacecraft, including satellites and other space probes.

Defense and military applications

7475 T7351 T651 has been widely used in the military field for its excellent anti-ballistic properties and is used to manufacture military aircraft, missiles and armored vehicles.

Auto industry

7075 T7351 aluminum plate is used for lightweight and high-strength parts of automobiles, such as braking systems and body structures. 7475 T651 aluminum plate can be used in body frames and engine parts to improve the vehicle's lightweight and fuel efficiency.

Shipbuilding

The corrosion resistance of 7475 T7351 aluminum plate makes it suitable for marine environments and may be used in the manufacture of ships, especially parts that require high strength and lightweight. 7475 T651 is commonly used in the manufacture of structural components of ships, such as hulls and plating.

Sports equipment

7475 T7351 T651 aluminum plate, due to its strength and lightness, this aluminum plate may also be used to manufacture sports equipment such as bicycles, motorcycles and sports equipment.

High pressure vessel

The high strength of 7475 T7351 T651 aluminum plate makes it an ideal choice for manufacturing high-pressure vessels, such as gas cylinders, oil tanks, etc.

Related products