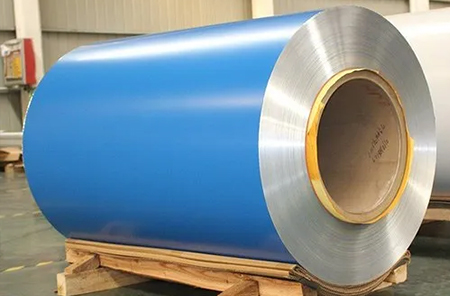

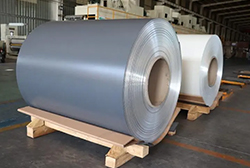

Color Coated Aluminum Sheet Coil

Color-coated aluminum coil sheets have good decorative properties and weather resistance and are widely used in aluminum-plastic panels, industrial factory roofs, curtain walls, aluminum shutters, cans, cosmetic lids, and electronic and electrical panels..

Specifications of chalco color coated aluminum coil sheet

Alloy: 1050 1060 1100 3003 3004 3105 5052 5083

Temper: H42 H44 H46

Color: RAL color, or press to confirm sample (customized)

Coating: PE,PVDF, EPOXY

Coating thickness: single coating (4μm-20μm); double coating (25μm-28μm); 3 coatings (35μm-38μm)

Hot selling sizes: 4'×6', 4'x 8' 4×10 foot, etc or Customized

Hot products of chalco color coated aluminum sheet coil

1060 color coated aluminum sheet coil

3003 color coated aluminum sheet coil

5052 color coated aluminum sheet coil

PE color coated aluminum sheet roll

PVDF color coated aluminum sheet coil

Wood grain color coated aluminum sheet roll

Marble pattern color coated aluminum sheet coil

Chameleon color coated aluminum sheet roll

Pearl color coated aluminum sheet coil

Application of Chalco color coated aluminum sheet coil

-

Architectural decoration

Architectural decorationColor-coated aluminum coils are mainly used in roofs, roof panels, curtain wall panels, ceiling panels, honeycomb panels, insulation panels, blinds, billboards, etc. in the field of architectural decoration.

-

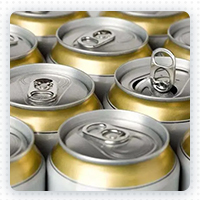

Food packaging

Food packagingColored aluminum coils are also widely used in food packaging, mainly manufacturing non-pressure food cans, pressure food cans, can lids, bottle caps, pull rings, food boxes, various food packaging sealing bags, etc.

-

Electronic and electrical appliances

Electronic and electrical appliancesColored aluminum coils are mainly used in electronics and appliances to manufacture air conditioner panels, washing machine panels, refrigerator panels, and cabinet panels.

-

Printing

PrintingColor-coated aluminum coils are mainly used to produce PS boards, CTP boards, UV-CTP printing plates, etc. in the printing field.

-

Transportation

TransportationManufacturing of exterior and interior walls of vans, body panels, train carriage panels, ship interior panels, traffic signs, etc.

Advantages of Chalco color coated aluminum sheet coil

- There is a dense oxide film on the surface, which has strong adhesion, oxidation resistance, acid resistance, alkali resistance, corrosion resistance, and UV resistance.

- It has strong impact resistance, high resistance, no damage to the surface paint, and is suitable for areas with common sandy weather.

- Chalco has introduced imported molding and painting production lines and controls all processes in-house. With a stable quality system, the adhesion between the coating and the metal is better, the color is uniform, the colors are diverse, and the user has a large choice space.

- It is easy to construct and can cooperate with planners to produce various shapes to reduce construction costs.

- It can be freely cut, slit, arced, balanced, and drilled for seam fixing and edge compression molding.

- It is highly decorative, painted with wood grain and stone grain, has a realistic physical texture, and has a vivid natural beauty.

What else do you want to know about Chalco color-coated aluminum coils?

What coating materials are available for Chalco color-coated aluminum coils?

Color-coated aluminum coils can use a variety of coating materials. Different coating materials will affect its weather resistance and service life. Commonly used coating materials for Chalco color-coated aluminum coils include high-quality PE, PVDF, etc. To learn more about other coating materials, please click 6 common coatings for color-coated aluminum coils.

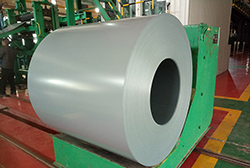

Chalco color coated aluminum coil production process flow

The production process of Chalco color-coated aluminum coils has five steps, including aluminum coil pretreatment, paint application, drying and curing, cutting, inspection and packaging. For details, please refer to the 5 production steps of color-coated aluminum coils.

Is Chalco a factory?

Chalco is a manufacturer of deadly color-printed aluminum coils. The coating adopts an internationally advanced precision three-mix reverse mixing machine. Precision coating is carried out in a closed and dust-free state, so that the coating film thickness and coating appearance quality are improved. Control to ensure the quality of products delivered to customers.

How to pack Chalco color picture aluminum coils?

Pack and label in accordance with regulations and customer requirements to avoid any possible damage during storage or transportation.