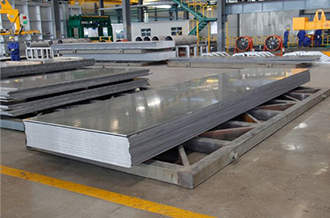

5083 H32 Aluminum Plate

Aluminum 5083 UNS-A95083 aluminum alloy is known for its excellent performance in the most extreme environments and has strong resistance to corrosion from seawater and industrial chemical environments. 5083 aluminum alloy sheet has the highest strength among 5000 series non heat treatable alloys, and its strength is high in the tempered temper.

The 5083 aluminum plate in H32 temper is processed by work hardening the material after rolling, and then stabilized to a quarter hardness through low-temperature heat treatment, with moderate hardness. 5083-H32 aluminum plate achieves a balance between strength and corrosion resistance, and is suitable for fields such as ship plates and tank bodies that require certain strength and corrosion resistance.

Chalco 5083 H32 aluminum plate stock size

| Description | Thickness (inch) | Thickness (mm) | Width (inch) | Length (inch) |

|---|---|---|---|---|

| 5083-H32 ALUM PLT .118" ASTM B209 | 0.118 | 3 | 60 | 118 |

| 5083-H32 ALUM PLT .200" ASTM B209 | 0.200 | 5 | 60 | 118 |

| 5083-H32 ALUM PLT .236" ASTM B209 | 0.236 | 6 | 60 | 118 |

| 5052 H32 AMS-QQA-250/8 .2500x48.0000x48 | 0.250 | 6.35 | 48 | 96 |

| 5083-H32 ALUM PLT .250" ASTM B209 | 0.250 | 6.35 | 48 | 144 |

| 5083-H32 ALUM PLT .315" ASTM B209 | 0.315 | 8 | 60 | 118 |

| 5083-H32 ALUM PLT .375" ASTM B209 | 0.375 | 9.53 | 48 | - |

| 5083-H32 ALUM PLT .500" ASTM B209 | 0.500 | 12.70 | 48 | - |

| 5083-H32 ALUM PLT .625" ASTM B209 | 0.625 | 15.88 | 48 | - |

| 5083-H32 ALUM PLT .750" ASTM B209 | 0.750 | 19.05 | 48 | - |

| 5083-H32 ALUM PLT 1.250" ASTM B209 | 1.250 | 31.75 | 48 | - |

Mechanical properties of 5083 H32 aluminum plate

| Specified thickness mm | Tensile strength Rm MPa | Yield strength Rp0,2 MPa | Elongation min. % | Bend radiusa | Hardness HBWa | ||||

|---|---|---|---|---|---|---|---|---|---|

| over | up to | min. | max. | min. max. | A50mm | A | 180° | 90° | |

| 0.2 | 0.5 | 305 | 380 | 215 | 5 | - | 2.0t | 0.5t | 89 |

| 0.5 | 1.5 | 305 | 380 | 215 | 6 | - | 2.0t | 1.5t | 89 |

| 1.5 | 3.0 | 305 | 380 | 215 | 7 | - | 3.0t | 2.0t | 89 |

| 3.0 | 6.0 | 305 | 380 | 215 | 8 | - | 2.5t | 89 | |

| 6.0 | 12.5 | 305 | 380 | 215 | 10 | - | 3.5t | 89 | |

| 12.5 | 40.0 | 305 | 380 | 215 | - | 9 | 0.5t | 89 | |

Chemical properties of 5083 H32 aluminum plate

| Element | Composition % (BS EN 573-3) |

|---|---|

| Mn | 0.40-1.00 |

| Fe | 0.00-0.40 |

| Cu | 0.00-0.10 |

| Mg | 4.00-4.90 |

| Si | 0.00-0.40 |

| Zn | 0.00-0.25 |

| Cr | 0.05-0.25 |

| Ti | 0.00-0.15 |

| Other (Each) | 0.00-0.05 |

| Others (Total) | 0.00-0.15 |

| Al | Balance |

Thermal properties of 5083 H32 aluminum plate

| Thermal properties | Metric | English | Comments |

|---|---|---|---|

| CTE, linear | 22.3 µm/m-°C @Temperature -50.0-20.0 °C | 12.4 µin/in-°F @Temperature -58.0-68.0 °F | - |

| 23.8 µm/m-°C @Temperature 20.0-100 °C | 13.2 µin/in-°F @Temperature 68.0-212 °F | AA; Typical; average over range | |

| 24.2 µm/m-°C @Temperature 20.0-100 °C | 13.4 µin/in-°F @Temperature 68.0-212 °F | - | |

| 25.0 µm/m-°C @Temperature 20.0-200 °C | 13.9 µin/in-°F @Temperature 68.0-392 °F | - | |

| 26.0 µm/m-°C @Temperature 20.0-300 °C | 14.4 µin/in-°F @Temperature 68.0-572 °F | - | |

| Specific Heat Capacity | 0.900 J/g-°C | 0.215 BTU/lb-°F | - |

| Thermal Conductivity | 117 W/m-K | 812 BTU-in/hr-ft²-°F | - |

| Melting Point | 590.6-638 °C | 109 -1180 °F | AA; Typical range based on typical composition for wrought products >= 1/4 in. thickness |

| Solidus | 590.6 °C | 1095 °F | AA; Typical |

| Liquidus | 638 °C | 1180 °F | AA; Typical |

Application of 5083 H3 aluminum plate

The strength of 5083 alloy in H32 temper is slightly higher than that in soft annealed O temper, but lower than that in marine temper H116 and H321 temper, and all properties are relatively balanced and stable. 5083 H32 aluminum plate is suitable for cold forming and can be applied to various forming processes to improve its processing flexibility.

5083 H32 treat checkered aluminum plate

5083 H32 aluminum plate has moderate strength, excellent corrosion resistance, and good formability, making it an ideal choice for manufacturing aluminum alloy patterns. It can be used as a bottom plate, step, and anti slip function in environments such as ships, industry, and chemical industry.

5083 H32 marine grade aluminum plate

- The quality of 5083 H32 marine aluminum plate meets the standards of ABS, BV, CCS, DNV, KR, LR, NK, RINA and other ship classifications, and ensures price competitiveness.

- 5083 H32 aluminum plate is suitable for ship hull parts with moderate requirements for corrosion resistance and strength, such as ship decks, ship support structures, etc. It can simultaneously meet the requirements of strength, corrosion resistance, and processing flexibility.

5083 H32 auto body sheet

- Chalco 5083 H32 aluminum plate can reach a maximum width of 2650mm, and can provide surface treatment, precision machining, cutting, stamping, and other deep processing to provide customers with overall automotive aluminum plate project solutions.

- 5083 H32 aluminum plate has slightly higher strength than the soft annealed state and is suitable for use in automotive coverings, body structural supports, interior panels, mailboxes, mudguards, etc.

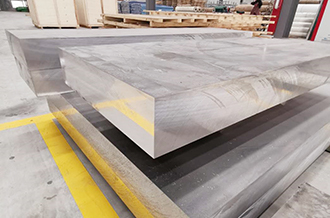

5083 H32 tank car aluminum plate

- Chalco 5083 H32 ultra wide aluminum plate has good formability and is widely used in the manufacturing of tank trucks, improving the overall formability of tank bodies.

- The corrosion resistance of 5083 H32 aluminum plate enables it to be used as a tank for transporting various materials, including easily corrosive materials such as chemicals.

- The H32 aluminum plate is suitable for cold forming, which increases the flexibility of the manufacturing process. Suitable for tank support structures, connecting parts, and special shaped liquid inlet and outlet parts.

Related products